What is a Throttling Valve? | Definition, Applications, Working, Examples, Selection

A throttling valve is a device that regulates the flow rate of a fluid or gas in a pipe or duct by constricting or expanding the diameter of the passage through which the fluid or gas flows. It is also known as a flow control valve, flow restricting valve, or rate-of-flow valve. There are several types of throttling valves, each with its own specific design and characteristics.

Throttling valves can be operated manually, by turning a handle or lever, or automatically, using an actuator such as an electric motor or a pneumatic cylinder. They are used in a variety of applications, including HVAC systems, process control systems, power generation systems, and many more.

Working of Throttling Valve

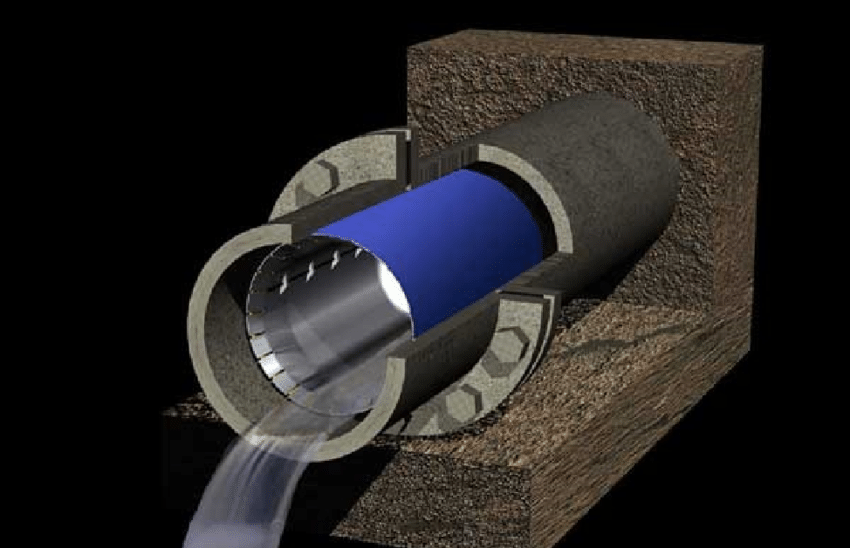

A throttling valve is a type of flow control valve that is used to regulate the flow of a fluid in a pipe or system. The valve works by constricting or narrowing the flow of fluid through a restriction, such as a disk or a cone, which is attached to a stem that is operated by a handle or a motor.

When the handle or motor is turned to open the valve, the restriction is moved away from the pipe or system, allowing more fluid to flow through. When the handle or motor is turned to close the valve, the restriction is moved closer to the pipe or system, reducing the amount of fluid that can flow through.

Throttling valves are commonly used in a wide variety of applications, including HVAC systems, process control, and industrial systems. They are used in situations where the flow of fluid needs to be adjusted or regulated, such as in systems where the pressure or temperature needs to be maintained at a specific level.

The valve can be operated manually or automatically by a control system, which can monitor the flow rate and pressure in the system, and adjust the valve position accordingly. Automatic valves can also be actuated by electrical signals or by pneumatic or hydraulic systems.

The working principle of a throttling valve is based on the fluid dynamics, where the pressure drop across the valve is directly proportional to the flow rate of the fluid. The pressure drop is created by the restriction inside the valve, which creates a resistance to the flow, causing the fluid to slow down and the pressure to drop.

Throttling valves are widely used in many industrial and commercial applications where the flow of a fluid must be controlled and regulated. They are important components in maintaining the proper operation of these systems, and it is important to use the correct type of valve for the specific application and fluid being used.

Example of Throttling Valve

One common example of a throttling valve is a radiator valve. Radiator valves are used to control the flow of hot water or steam through the radiators in a heating system. The valve typically consists of a handle or knob that is connected to a stem, which moves a restriction (such as a disk or cone) inside the valve. When the handle is turned to open the valve, the restriction is moved away from the pipe, allowing more hot water or steam to flow through the radiator, resulting in the room being heated. When the handle is turned to close the valve, the restriction is moved closer to the pipe, reducing the amount of hot water or steam that can flow through the radiator, resulting in the room getting cooler.

Another example is the flow control valve in a water supply system. This valve is used to control the flow of water to a specific area or to a specific fixture, such as a showerhead or a faucet. The valve typically consists of a handle or knob that is connected to a stem, which moves a restriction inside the valve. When the handle is turned to open the valve, the restriction is moved away from the pipe, allowing more water to flow through. When the handle is turned to close the valve, the restriction is moved closer to the pipe, reducing the amount of water that can flow through.

In industrial process and chemical plants, one example is the control valve that regulates the flow of a chemical or a gas. This type of valve typically uses an actuator, which can be pneumatic or electric, to move the restriction inside the valve. The actuator is controlled by a control system, which monitors the flow rate and pressure in the system, and adjusts the valve position accordingly.

Selection of Throttling Valve

Selecting the appropriate throttling valve for a specific application involves several factors that need to be considered. Here are a few key considerations when selecting a throttling valve:

- Fluid Type: The type of fluid that will be flowing through the valve must be considered, as different fluids have different properties, such as viscosity, density, and chemical compatibility. It is important to choose a valve that is compatible with the fluid and will not degrade or be damaged by it.

- Flow Rate: The flow rate of the fluid that will be flowing through the valve must be considered. The valve must be able to handle the maximum flow rate that the system will require, and it must also be able to adjust the flow rate as needed.

- Pressure: The pressure of the fluid that will be flowing through the valve must be considered. The valve must be able to handle the maximum pressure that the system will require, and it must also be able to maintain a stable pressure as the flow rate is adjusted.

- Temperature: The temperature of the fluid that will be flowing through the valve must be considered. The valve must be able to handle the maximum temperature that the system will require, and it must also be able to maintain a stable temperature as the flow rate is adjusted.

- Application: The specific application that the valve will be used in must be considered. Different applications have different requirements, such as flow rate, pressure, and temperature, so it is important to choose a valve that is designed for the specific application.

- Actuation: The actuation method of the valve must be considered. For example, manual valves are operated by hand, while automatic valves are operated by an actuator, such as an electric motor or a pneumatic cylinder.

Applications of Throttling Valve

Throttling valves are used in a wide range of applications and industries to control and regulate the flow of fluids and gases. Some common applications include:

- HVAC systems: Throttling valves are used to control the flow of air and water in heating, ventilation, and air conditioning systems. They are used to adjust the temperature and airflow rate in buildings and other structures.

- Process control systems: Throttling valves are used to control the flow of fluids and gases in industrial process control systems. They are used in chemical processing plants, oil refineries, and other industrial facilities to control the flow rate of fluids and gases.

- Power generation systems: These valves are used to control the flow of steam and other fluids in power generation systems. They are used in power plants, turbines, and other equipment to control the flow rate of fluids and gases.

- Oil and gas production: These valves are used to control the flow of oil and gas in production and transportation systems. They are used to control the flow rate of fluids and gases in drilling and production equipment, pipelines, and storage tanks.

- Water treatment: These valves are used to control the flow of water in water treatment systems. They are used to control the flow rate of water in filtration systems, sewage treatment plants, and other water treatment equipment.

- Food and Beverages: These valves are used to control the flow of fluids and gases in food and beverage manufacturing and processing plants. They are used to control the flow rate of fluids and gases in bottling, canning, and packaging equipment.

- Pharmaceuticals: These valves are used to control the flow of fluids and gases in pharmaceutical manufacturing and processing plants. They are used to control the flow rate of fluids and gases in tablet and capsule filling equipment.

- Automotive: These valves are used to control the flow of fluids and gases in automotive systems. They are used to control the flow rate of fluids and gases in fuel, cooling and lubrication systems.

This is not an exhaustive list, throttling valves are versatile and can be used in many other applications where flow rate control is required.

Advantages and Disadvantages of Throttling Valve

Advantages of Throttling Valves:

- Flow Control: Throttling valves are specifically designed to control the flow of fluid through a pipe or system, which allows for precise and accurate flow regulation.

- Pressure Control: Throttling valves can also be used to control the pressure in a system by adjusting the flow rate of the fluid.

- Easy to Use: Throttling valves are relatively simple and easy to operate, with manual valves being operated by a handle or knob, and automatic valves being operated by an actuator or control system.

- Versatility: Throttling valves are widely used in many different systems and applications, including HVAC, water supply, industrial and chemical processes, and many more.

- Durable: Throttling valves are typically made from materials that are strong and durable, such as metal or plastic, which allows them to withstand high pressures, temperatures, and flow rates.

Disadvantages of Throttling Valves:

- Cost: Throttling valves can be relatively expensive, particularly when compared to other types of valves, such as gate valves or ball valves.

- Maintenance: Throttling valves may require regular maintenance to ensure that they are working correctly and to prevent leakage.

- Limited Flow Range: Throttling valves are designed to control the flow rate of fluid, but they may not be able to handle large flow rate variations.

- Pressure Drop: Throttling valves create a pressure drop across the valve, which can be significant depending on the flow rate and the design of the valve.

- Accuracy: The accuracy of the flow control may vary depending on the design of the valve and the quality of the manufacturing process.

- Limited Life time: The life time of the throttling valve may be limited, especially if the valve is not operated within the manufacturer’s recommended conditions.

It is important to weigh the advantages and disadvantages of throttling valves when deciding whether to use them in a specific application. It is also important to consult with a professional or the valve manufacturer to ensure that the right type of valve is selected for the specific application and system.