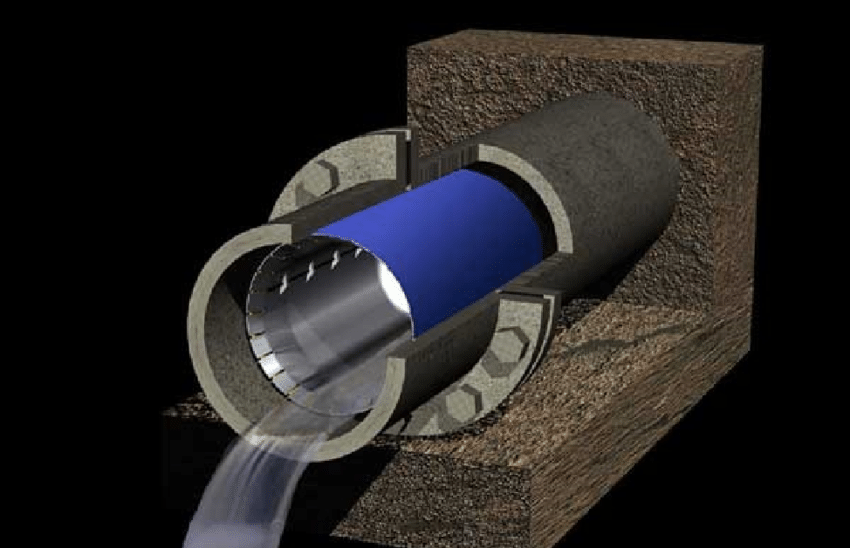

A pipe sleeve is a cylindrical piece of material that is inserted into an existing pipe to reinforce or repair the pipe. It can be made of various materials such as metal, plastic or composite and can be used to repair or reinforce a pipe that has become damaged, corroded or is no longer able to handle the pressure or flow of the fluid or gas passing through it.

Pipe sleeves are typically made from materials such as metal, plastic, or composite materials. The type of material used for a pipe sleeve will depend on the specific application and the environment in which the pipe will be used.

There are several types of pipe sleeves, including:

- Reinforcement sleeves: These are used to reinforce existing pipes, such as those that have become corroded or have been damaged by external forces.

- Repair sleeves: These are used to repair a damaged pipe, such as one that has a hole or crack.

- Encasement sleeves: These are used to encase an existing pipe, such as one that is made of an outdated material or is no longer able to handle the pressure or flow of the fluid or gas passing through it.

- Expansion sleeves: These are used to accommodate thermal expansion of the pipe, they allow the pipe to expand and contract without putting strain on the pipe or the piping system.

- Fireproofing sleeves: These are used to provide fire resistance to a pipe, they are made of fireproofing materials and can be used to protect pipes that run through areas where fire is a concern.

Pipe sleeves are commonly used in industrial and commercial facilities, and are an effective way to repair, reinforce or protect a pipe without having to replace the entire pipe.

Functions of Pipe Sleeves

A pipe sleeve is a cylindrical piece of material that is inserted into a pipe or a pipe fitting to protect it from external damage or to reinforce the pipe. The main functions of a pipe sleeve include:

- Protection: A pipe sleeve helps to protect the pipe from external damage caused by impact, abrasion, or corrosion. This can prolong the life of the pipe and reduce the need for repairs or replacement.

- Reinforcement: A pipe sleeve can be used to reinforce a pipe that is weak or damaged. This can help to increase the structural integrity of the pipe and improve its ability to handle pressure and load.

- Isolation: A pipe sleeve can be used to isolate one pipe from another, to prevent the transfer of heat, sound, or vibration between them.

- Support: A pipe sleeve can be used to support and hold a pipe in place, which can help to prevent movement or damage caused by thermal expansion or contraction.

- Sealing: A pipe sleeve can be used to seal a pipe or pipe fitting, which can help to prevent leaks and protect against contamination.

Working of Pipe Sleeves

Pipe sleeves work by encasing or covering the pipe or pipe joint that they are protecting. They are typically inserted over the pipe or joint and then secured in place, either by welding, bolting, or adhesive. The sleeve acts as a barrier between the pipe and the external environment, protecting the pipe from damage and corrosion.

There are different types of pipe sleeves, such as split sleeves and full encirclement sleeves, that have different methods of installation and provide different levels of protection.

Split sleeves are used to repair or reinforce existing pipes. They are split down the middle, allowing them to be wrapped around the pipe and then secured in place. These types of sleeves are typically used when a pipe has been damaged or is in danger of failing and needs to be reinforced.

Full encirclement sleeves, also known as wraparound sleeves, provide complete protection for a pipe or joint. They are used to provide protection for new pipes or to upgrade the protection of existing pipes. They are typically a single piece of material that encircles the entire circumference of the pipe and is secured in place.

In both cases, the pipe sleeves are used to add an additional layer of protection to the pipes. The sleeves can withstand external forces such as impact, vibration, and weather, preventing the pipe from being damaged and prolonging its lifespan.

Pipe sleeves work by encasing or covering the pipe or pipe joint they are protecting, acting as a barrier between the pipe and the external environment. They are secured in place and provide protection from wear and tear, corrosion, and damage from external factors such as impact, vibration, and weather. The different types of pipe sleeves have different methods of installation and provide different levels of protection.

Use of Pipe Sleeves

Pipe sleeves have a wide range of uses in various industries and applications. Some of the most common uses of pipe sleeves include:

- Construction: Pipe sleeves are commonly used in construction to protect pipes during transportation and installation. They can also be used to reinforce pipes in load-bearing walls or floors.

- HVAC: Pipe sleeves are used in heating, ventilation, and air conditioning systems to protect pipes from damage and to isolate them from other building components.

- Plumbing: Pipe sleeves are used in plumbing systems to protect pipes from damage and to reinforce them in areas where they may be subject to heavy loads or vibration.

- Industrial: Pipe sleeves are used in industrial settings to protect pipes from damage caused by impact, abrasion, or corrosion. They can also be used to isolate and insulate pipes carrying hazardous materials.

- Marine: Pipe sleeves are used in marine environments to protect pipes from damage caused by saltwater and marine organisms. They can also be used to reinforce pipes in ships and offshore platforms.

- Power Generation: Pipe sleeves are used to protect and reinforce pipes in power generation plants and in other critical infrastructure facilities.

- Mining: Pipe sleeves are used to protect and reinforce pipes in mining operations, where they may be subject to impact and abrasion.

- Oil and Gas: Pipe sleeves are used to protect and reinforce pipes in oil and gas operations, where they may be subject to impact, abrasion, and corrosion.

Applications of Pipe Sleeve

A pipe sleeve is a cylindrical piece of material that is used to encase or protect a pipe or a pipe joint. The main purpose of a pipe sleeve is to provide mechanical and corrosion protection for the pipe. There are several different types of pipe sleeves, including split sleeves, which are used to repair or reinforce existing pipes, and full encirclement sleeves, which are used to provide complete protection for a pipe or joint.

Pipe sleeves can be made from a variety of materials, including metal (such as stainless steel or aluminum), plastic, or rubber. The material choice will depend on the specific application and the type of pipe being protected.

These sleeves can be used in many different industries such as oil and gas, water and sewage, construction, and transportation. They are used to protect pipes from wear and tear, corrosion, and damage from external factors such as weather, vibration, and impact. They can also be used to repair or reinforce existing pipes, or to provide additional support for new pipes.

These sleeves are cylindrical pieces of material that are used to protect or repair pipes. They can be made from a variety of materials and are used in many different industries to protect pipes from wear and tear, corrosion, and damage from external factors.

Advantage and Disadvantage of Pipe Sleeve

Here are some advantages and disadvantages of using pipe sleeves:

Advantages:

- Protection: They provide a barrier between the pipe and external elements, protecting the pipe from damage caused by impact, abrasion, or corrosion.

- Reinforcement: They can be used to reinforce weak or damaged pipes, increasing their structural integrity and ability to handle pressure and load.

- Isolation: They can be used to isolate one pipe from another, preventing the transfer of heat, sound, or vibration between them.

- Support: They can be used to support and hold pipes in place, preventing movement or damage caused by thermal expansion or contraction.

- Sealing: They can be used to seal pipes and pipe fittings, preventing leaks and protecting against contamination.

- Cost-effective: They are relatively inexpensive and can be a cost-effective solution for protecting and reinforcing pipes.

Disadvantages:

- Installation: These can be difficult to install, especially in tight spaces or when access is limited.

- Maintenance: These require regular inspection and maintenance to ensure they are functioning properly and to detect any damage or wear.

- Compatibility: These may not be compatible with certain types of pipes or in certain environments, requiring the use of specialized sleeves.

- Limited access: These may make it difficult to access the pipe for repair or maintenance, which can increase downtime and cost.

- Not suitable for all types of corrosion: Some types of corrosion can still occur even with the use of pipe sleeves.

These are a cost-effective solution for protecting and reinforcing pipes, but they can be difficult to install and maintain, and may not be suitable for all types of corrosion. Careful consideration should be given to the specific application and environment before deciding to use pipe sleeves.

They are typically made from materials such as metal, plastic, or composite materials, depending on the application and environment. They have a wide range of uses, including construction, HVAC, plumbing, industrial, marine, power generation, mining and oil and gas industry.

Pipe sleeves can be installed in various ways such as wrapping around the pipe, sliding over the pipe, or by welding to the pipe. They are commonly used in both new construction and repair and maintenance of existing systems. They are also an important component in corrosion protection system for pipelines.