A temperature control valve is a type of valve that regulates the flow of a fluid (such as water or steam) in order to maintain a desired temperature in a system. These valves typically use a thermostat or temperature sensor to detect changes in temperature, and then adjust the flow of fluid accordingly in order to maintain a constant temperature.

They can be used in a variety of applications, such as HVAC systems, industrial process control, and power generation. Depending on the application, temperature control valves can be designed to work with different types of fluids, at varying temperatures and pressures, and with different levels of precision and accuracy. Some common types of temperature control valves include globe valves, butterfly valves, and ball valves

These control valves can be either on-off or modulating. On-off valves are designed to open or close fully to control the flow of fluid, while modulating valves are designed to control the flow of fluid by adjusting the position of the valve. This allows modulating valves to maintain a more precise temperature control.

There are different types of actuators used to operate temperature control valves, including pneumatic, electric and hydraulic. Pneumatic actuators use compressed air to open and close the valve, while electric actuators use an electric motor to control the position of the valve. Hydraulic actuators use fluid pressure to open and close the valve.

Temperature control valves are also available in different types of constructions, including cast iron, bronze, stainless steel, and plastic. The type of construction selected depends on the application, temperature and pressure range, and the type of fluid being used.

Temperature control valves can be used in various types of applications, including HVAC systems, industrial process control, and power generation. In HVAC systems, temperature control valves are used to control the flow of hot or cold water to maintain a comfortable temperature in a building. In industrial process control, temperature control valves are used to control the temperature of industrial processes such as distillation, fermentation, and chemical reactions. In power generation, temperature control valves are used to control the temperature of steam in power plants.

One new advancement in temperature control valves is the use of smart technology and digital communication. Some temperature control valves now have built-in sensors and can be connected to a building management system or industrial control system, allowing for remote monitoring and control of the temperature. This can improve the efficiency and accuracy of temperature control, as well as provide valuable data for troubleshooting and maintenance.

Another new development is the use of self-actuated temperature control valves, which use a built-in sensor to detect changes in temperature and adjust the flow of fluid without the need for an external controller. This can simplify the design of the system and reduce costs.

Additionally, there are temperature control valves that are specifically designed to meet the needs of specific industries or applications. For example, there are valves that are designed to withstand high temperatures and pressures, making them suitable for use in power generation and chemical processing. There are also valves that are designed to be highly accurate and precise, making them suitable for use in laboratory and research applications.

Lastly, with the increasing focus on energy efficiency and reducing carbon footprint, temperature control valves are also designed to be more energy efficient. They are designed to minimize the energy required to control the temperature, which results in energy savings and reduction in the carbon footprint.

Working Of Temperature Control Valve

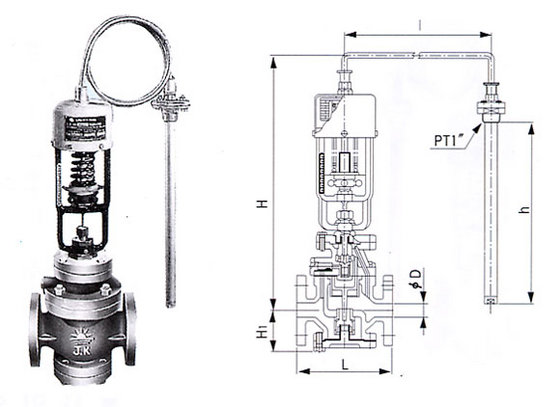

It typically consists of a valve body, a temperature sensor, and a control mechanism.

The temperature control valve works by adjusting the flow of fluid through the system based on the temperature measured by the sensor. When the temperature of the fluid is below the desired setpoint, the control mechanism opens the valve to allow more fluid to flow through, which increases the temperature. When the temperature is above the setpoint, the control mechanism closes the valve to reduce the flow of fluid and decrease the temperature.

The control mechanism can take different forms, such as a pneumatic or electric actuator, and can be controlled by a manual or automatic controller. The controller receives the temperature input from the sensor and compares it to the setpoint. Depending on the difference between the measured temperature and the setpoint, the controller sends a signal to the actuator to open or close the valve.

A temperature control valve can be used in a variety of applications such as HVAC systems, industrial process control, and temperature control in power plants. These valves can be found in numerous industrial settings such as chemical, food, and pharmaceutical processes. These valves can be used to control the temperature of liquids and gases, and can be designed for high-pressure, high-temperature, or corrosive environments.

A temperature control valve is a crucial component in maintaining a stable temperature in a system, and it can help to improve the efficiency, safety, and performance of the system

Applications of Temperature Control Valve

Temperature control valves are devices that regulate the flow of a fluid, such as water or steam, to maintain a specific temperature within a system. They are commonly used in industrial and commercial settings, as well as in residential heating and cooling systems.

One common application of temperature control valves is in HVAC systems, where they are used to control the temperature of air or water flowing through the system. This helps to ensure that the air or water temperature in a building or facility is maintained at a comfortable level for occupants.

Another application of temperature control valves is in industrial process control, where they are used to regulate the temperature of liquids or gases in manufacturing processes. This helps to ensure that the process is operating at the correct temperature for optimal efficiency and to prevent damage to equipment.

Temperature control valves can also be used in refrigeration systems, where they are used to control the flow of refrigerant and maintain the desired temperature in refrigerated spaces.

In addition, temperature control valves can be used in heating systems, such as boilers, to maintain the temperature of the water used in the heating system. This helps to ensure that the water is at the correct temperature for efficient heating and to prevent damage to the boiler.

In summary, temperature control valves are widely used in many different applications to control the flow of fluids and maintain a specific temperature within a system to ensure optimal efficiency and prevent damage to equipment.

Types of Temperature Control Valve

There are several types of temperature control valves, each with their own unique features and applications.

- Linear temperature control valves – These are designed to control the flow of fluid in a linear fashion, meaning the flow rate is directly proportional to the valve’s position. This type of valve is commonly used in heating and cooling systems.

- Modulating temperature control valves – These valves are similar to linear valves, but they can also be adjusted to modulate the flow rate. This allows for more precise temperature control.

- Two-way temperature control valves – They have two ports, one for inlet and one for outlet, and are used to control the flow of fluid in one direction. They are typically used in heating and cooling systems.

- Three-way temperature control valves – The valves have three ports, one for inlet, one for outlet, and one for bypass. They are used to control the flow of fluid in two directions, allowing for more precise temperature control.

- Differential temperature control valves – They are basically designed to sense the difference in temperature between two points and adjust the flow of fluid accordingly. They are commonly used in heating and cooling systems to maintain a specific temperature difference.

- Electronic Temperature control valve – These valves are controlled by an electronic signal, typically a voltage or current, and are used in applications where precision and fast response time are required.

- Motorized Temperature control valve – These are operated by an electric motor and are used in applications where a high flow rate or remote control is required.

All of these valves are used to control the flow of fluid in a system to maintain a specific temperature. The choice of valve will depend on the specific requirements of the application.

Pros of Temperature Control Valve

- High precision: Use of these valves can provide precise temperature regulation, allowing for accurate control of the process or system.

- Energy efficiency: By maintaining a consistent temperature, these valves can help to reduce energy consumption and costs.

- Safety: Temperature control valves can help to prevent overheating and other dangerous conditions, improving safety for operators and equipment.

- Long service life: With proper maintenance, of the valves, then they can have a long service life and provide reliable performance over time.

Cons of Temperature Control Valve

- Cost: These control valves can be expensive to purchase and install, especially for larger or more complex systems.

- Maintenance: These valves mostly require regular maintenance and calibration to ensure proper operation, which can be costly and time-consuming.

- Sensitivity to fouling: These valves can be sensitive to fouling, which can affect performance and cause the valve to fail.

- Limited temperature range: Some of them may have limited temperature ranges, which can limit their use in certain applications.

These valves are a valuable tool for precise temperature regulation in a variety of systems, but they do come with some downsides. It’s important to weigh the pros and cons and consider the specific requirements of the application before deciding to use a temperature control valve.