How to Calculate Weight of a Steel Plate? Working, Functions, Factor Affecting and Formula

A steel plate is a flat piece of steel material with a thickness of 0.25 inches or more. It can be used in construction, structural engineering, and other applications where durability and strength are required. Steel plates can be made in various shapes and sizes, and can be further processed, such as by cutting, welding, or drilling, to fit specific needs. They are made from a combination of iron and carbon, and other alloying elements may be added to improve properties such as strength and corrosion resistance.

In addition to construction and engineering, steel plates are also used in a variety of other industries and applications, such as shipbuilding, manufacturing, heavy equipment manufacturing, and the oil and gas industry. They can be made in different grades, each with specific properties suited for different uses. For example, some grades are designed for high strength and toughness, while others are designed for improved corrosion resistance or better machinability. Steel plates can also be coated with various materials, such as paint or zinc, to improve their resistance to the elements or to provide other benefits. Steel plates can also be cut and formed into various shapes, such as rounds, squares, or rectangles, to suit specific needs.

Working of Steel Plate

Working with these plates involves a variety of processes to shape, cut, and finish the plates to meet specific needs. Some common processes used to work with these plates include:

- Cutting: Steel plates can be cut into various shapes and sizes using methods such as sawing, shearing, or plasma cutting.

- Drilling: Holes can be drilled into steel plates for various purposes, such as to create bolt holes or to accommodate piping.

- Bending: These plates can be bent into various shapes using a press brake or a roll bender.

- Forming: These can be formed into various shapes using a variety of methods, such as stamping or spinning.

- Rolling: The plates can be rolled into cylinders or cones using a roll forming machine.

- Grinding: These plates can be ground to remove burrs or to improve the surface finish.

- Welding: The plates can be joined together using various welding methods, such as MIG, TIG, or stick welding.

- Painting: These plates can be painted to protect them from the elements or to improve their appearance.

- Heat treatment: The plates can be heat-treated to improve their properties, such as strength and toughness.

It’s important to note that when working with the plates, proper safety precautions and equipment should be used, as the materials can be heavy and sharp edges can be present.

Steel Plate Calculator

A steel plate weight calculator is a tool that is used to determine the weight of a the plate. It can be used for both rectangular and circular plates. To use the calculator, you will need to know the length, width, and thickness of the plate, as well as the density of the steel.

The weight of a rectangular plate can be calculated by multiplying the length, width, and thickness, and then multiplying that number by the density of the steel. The formula for this calculation is:

Weight = (Length x Width x Thickness) x Density

For circular steel plates, the weight can be calculated by multiplying the radius squared, by the thickness, and then by the density of the steel. The formula for this calculation is:

Weight = (π x (Radius^2) x Thickness) x Density

It’s important to note that the density of steel can vary depending on the specific alloy used, but a typical density of steel is around 7.85 g/cm^3.

Some examples of Steel Plate weight calculator are available online, like “matweb.com”.

Formula of Calculating the Weight of Steel Plate

The formula for calculating the weight of a steel plate is:

Weight (kg) = (Length (m) x Width (m) x Thickness (mm) x Density (kg/m³))/ 1000

Or

Weight (lb) = (Length (ft) x Width (ft) x Thickness (in) x Density (lb/ft³))/ 4,409

Where:

- Length and Width are the dimensions of the plate.

- Thickness is the thickness of the plate, usually measured in millimeters or inches.

- Density is the density of the steel, usually measured in kilograms per cubic meter (kg/m³) or pounds per cubic foot (lb/ft³).

- The final result will be the weight of the steel plate in kilograms or pounds.

It’s important to note that the density of steel can vary depending on the specific alloy used, but a typical density of steel is around 7.85 g/cm³ or 0.2836 lb/in³

It’s also important to note that the formula is for a flat steel plate and it will be different for a circular plate.

How to Calculate the Weight of Carbon Steel Plate

To calculate the weight of a carbon steel plate, you will need to know the thickness of the plate and the dimensions (length and width). You will also need to know the density of carbon steel, which is typically around 7.85 g/cm³ (0.2836 lb/in³).

The formula for calculating the weight of a carbon steel plate is as follows:

Weight (kg) = (Length (m) x Width (m) x Thickness (mm) x Density (kg/m³))/ 1000

Weight (lb) = (Length (ft) x Width (ft) x Thickness (in) x Density (lb/ft³))/ 4,409

Example: If you have a carbon steel plate that is 1 meter long, 1 meter wide, and has a thickness of 10mm, the weight of the plate would be:

Weight (kg) = (1 x 1 x 10 x 7.85) / 1000 = 0.0785 kg

Weight (lb.) = (3.28 x 3.28 x 0.39 x 0.2836) / 4,409 = 0.1728 lb. It’s important to note that the density of steel can vary depending on the specific alloy used, but a typical density of carbon steel is around 7.85 g/cm³ or 0.2836 lb./in³.

Factors Affecting the Weight of Steel Plate

There are several factors that can affect the weight of a steel plate:

- Thickness: The thickness of the plate is one of the most important factors that determine the weight of the plate. As the thickness of the plate increases, the weight of the plate will also increase. This is because the thickness of the plate directly affects the volume of steel in the plate and therefore the weight of the plate.

- Density: The density of the steel used to make the plate will also affect the weight of the plate. Different types of steel have different densities, and so a plate made from a steel with a higher density will be heavier than a plate made from a steel with a lower density. For example, a plate made of low carbon steel will have a lower density than a plate made of high carbon steel.

- Length and width: The length and width of the plate also affect the weight of the plate. A larger plate will be heavier than a smaller plate of the same thickness. This is because the weight of the plate is directly proportional to the area of the plate.

- Temperature: Temperature can affect the weight of the steel plate as well. When the temperature increases, the steel expands and its weight increases. This is due to the coefficient of thermal expansion of steel, which means that the steel will expand slightly when it is heated and contract when it is cooled.

- Coating: If the steel plate is coated with any material such as paint or zinc, the weight of the plate will increase as well. The weight of the coating must be taken into account when calculating the total weight of the plate.

- Shape: The shape of the plate also affects the weight. A circular plate will be heavier than a rectangular plate of the same size and thickness. This is because a circular plate has a larger circumference, which means that it has a larger area and therefore more steel than a rectangular plate of the same size.

It is important to consider all of these factors when calculating the weight of a steel plate, as even small variations in thickness, density, length and width, temperature, coating, and shape can have a significant impact on the weight of the plate.

Functions of Steel Plate

Steel plates have a wide range of functions and applications. Some of the main functions of steel plates include:

- Construction: Steel plates are used in construction for building structures such as bridges, buildings, and towers. They provide a strong and durable foundation for these structures.

- Structural engineering: Steel plates are used in structural engineering for building frameworks and supports for various structures. They are used to distribute loads evenly across the structure and to provide stability and rigidity.

- Ships and boats: Steel plates are used in shipbuilding and boatbuilding for the construction of the hulls, decks, and superstructures. They provide a strong and durable foundation for these vessels.

- Heavy equipment: Steel plates are used in the manufacturing of heavy equipment such as bulldozers, excavators, and cranes. They provide a strong and durable foundation for these machines.

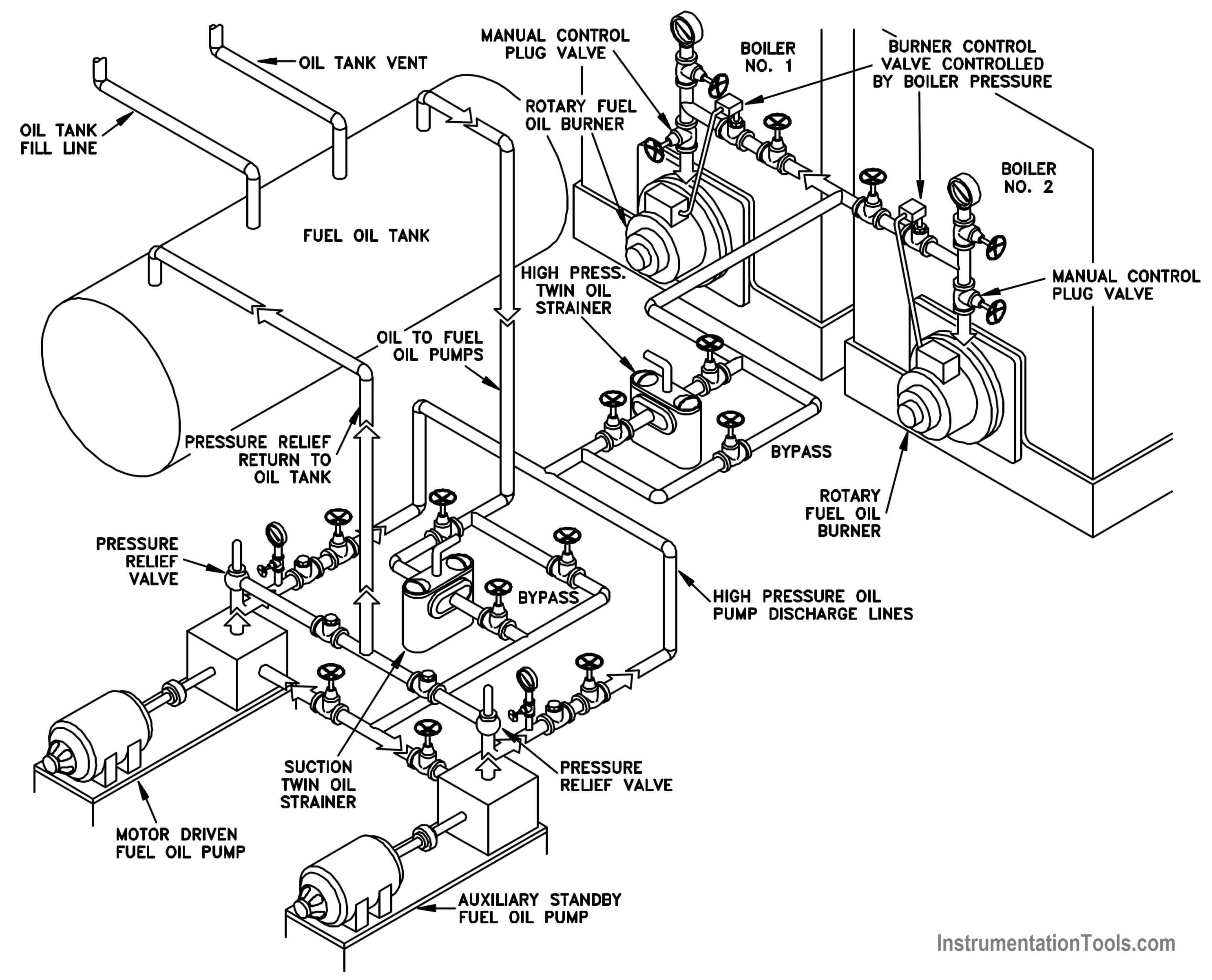

- Oil and gas: Steel plates are used in the oil and gas industry for the construction of pipelines and storage tanks. They provide a strong and durable foundation for these structures and are resistant to corrosion.

- Manufacturing: Steel plates are used in manufacturing for the construction of machinery, equipment, and tools. They provide a strong and durable foundation for these machines and tools.

- Defense: Steel plates are used in defense for the construction of tanks, armored vehicles, and other military equipment. They provide a strong and durable foundation for these vehicles and protect the occupants from enemy fire.

- Mining: Steel plates are used in mining for the construction of mining equipment, such as conveyor belts and crushing machines. They provide a strong and durable foundation for these machines and are resistant to wear and tear.

Steel plates can be cut, drilled, bent, formed, rolled, ground and welded to fit specific needs. They are also used in shipbuilding, heavy equipment manufacturing, oil and gas industry, manufacturing and defense.