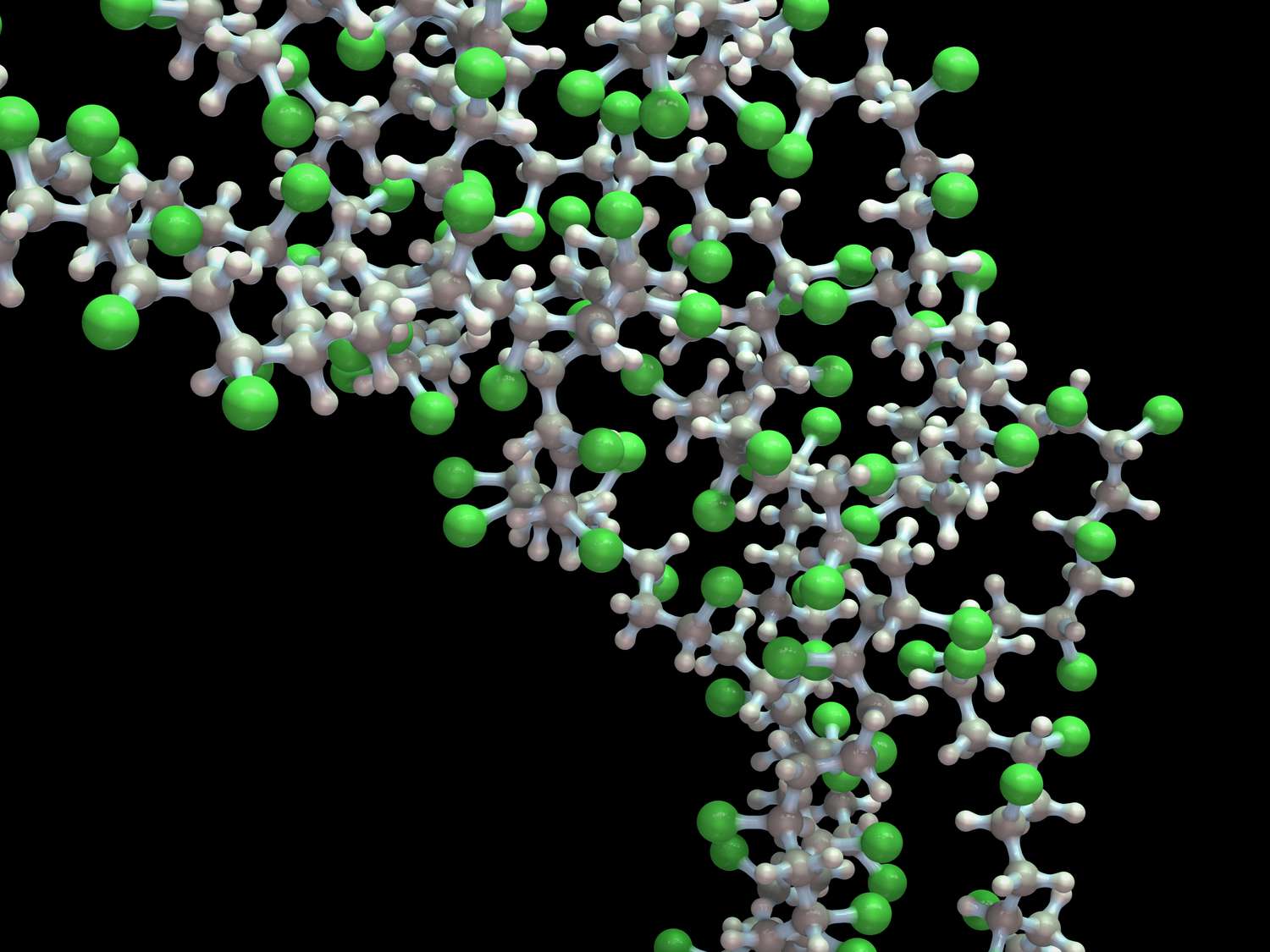

Polymers are large molecules made up of repeating units called monomers. These molecules can have a wide range of properties, depending on the type of monomers used and the way the polymer is formed. Some common examples of polymers include plastics, rubber, and fibers such as nylon and polyester. Polymer can be natural, such as cellulose in plants, or synthetic, such as those created in a laboratory. They are used in a wide variety of applications, from packaging materials and construction materials to medical devices and textiles.

Polymer can be divided into two main categories: thermoplastics and thermosetting polymers. Thermoplastics can be melted and reshaped multiple times, while thermosetting polymers solidify permanently once they are heated and cooled.

Thermoplastics include materials such as polyethylene, polypropylene, and polyvinyl chloride (PVC). They are used in applications such as packaging, toys, and automotive parts.

Thermosetting polymers include materials such as polyurethane, epoxy, and phenolic resins. They are used in applications such as adhesives, electrical laminates, and coatings.

Polymer can also be classified based on their molecular structure, such as linear polymers, branched polymers, and crosslinked polymers.

Polymer can be synthesized through various methods such as addition polymerization, condensation polymerization, and ring-opening polymerization, depending on the type of monomers used.

Due to their versatility and wide range of properties, polymers play a critical role in many industries, including manufacturing, construction, and medicine.

Types of Polymers

There are many different types of polymer, each with their own unique properties and applications. Some of the most common types of polymers include:

- Thermoplastics: These are polymer that can be melted and reshaped multiple times. Examples include polyethylene, polypropylene, and polyvinyl chloride (PVC). They are used in applications such as packaging, toys, and automotive parts.

- Thermosetting polymer: These are polymer that solidify permanently once they are heated and cooled. Examples include polyurethane, epoxy, and phenolic resins. They are used in applications such as adhesives, electrical laminates, and coatings.

- Elastomers: These are polymer that have high flexibility and elasticity. Examples include natural rubber and synthetic rubbers such as neoprene and silicone. They are used in applications such as tires, seals, and vibration-damping materials.

- Biopolymers: These are polymer that are derived from natural sources such as plants and animals. Examples include cellulose, starches, and proteins. They are used in applications such as food packaging and medical implants.

- Synthetic fibers: These are polymer that are used to make fibers for textiles. Examples include nylon, polyester, and acrylic. They are used in applications such as clothing, upholstery, and carpets.

- Polymer composites: These are materials that consist of a polymer matrix reinforced with fibers or particles. They are used in applications such as aircraft parts, sporting goods, and automotive components.

- Polymer blends: These are polymer that are made by mixing two or more different types of polymers. They are used in applications such as films, sheets, and coatings.

- Polymer foams: These are polymer that have been formulated to have a cellular structure, resulting in a lightweight and strong material. Examples include polystyrene and polyurethane foams. They are used in applications such as insulation, cushioning, and packaging.

This is not an exhaustive list and there are many other types of polymer that exist, and new types of polymer are developed every day.

Properties of Polymers

Polymers have a wide range of properties that depend on the type of monomers used and the way the polymer is formed. Some common properties of polymers include:

- Molecular weight: Polymer can have a wide range of molecular weights, from a few thousand to several million grams per mole. The molecular weight of a polymer affects many of its physical properties, such as viscosity, density, and solubility.

- Strength: Polymers can be strong and stiff, or weak and flexible, depending on their molecular structure and the way the polymer is formed.

- Thermal properties: Polymer can have a wide range of thermal properties, depending on the type of polymer and its molecular structure. Some polymers have high thermal stability and can withstand high temperatures, while others are sensitive to heat and can degrade at relatively low temperatures.

- Electrical properties: Polymer can be good insulators or conductors of electricity, depending on their chemical structure and the way the polymer is formed.

- Optical properties: Polymers can be transparent, translucent, or opaque, and can have a wide range of colors, depending on the type of polymer and its molecular structure.

- Solubility: Polymer can be soluble or insoluble in different solvents, depending on their chemical structure and the way the polymer is formed.

- Adhesion: Polymer can have good or poor adhesion to different surfaces, depending on their chemical structure and the way the polymer is formed.

- Durability: Polymer can be resistant or susceptible to different types of damage, such as UV light, chemicals, and mechanical stress, depending on their chemical structure and the way the polymer is formed.

- Biocompatibility: Some polymer are biocompatible and can be used in medical devices and implants, while others are not.

This is not an exhaustive list of properties and different polymer can have other properties as well. Some properties of polymers can be improved or modified through the use of various techniques such as blending, crosslinking and modification of the monomer units.

Uses of Polymers

Polymers have a wide range of uses due to their unique properties and versatility. Some common uses of polymers include:

- Packaging: Polymers are widely used in packaging materials such as plastic bags, bottles, and containers. They provide a barrier to moisture, oxygen, and other gases, which helps to preserve food and other products.

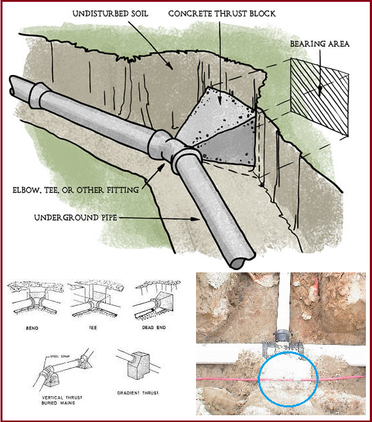

- Construction: Polymers are used in construction materials such as pipes, roofing, and insulation. They are lightweight and durable, and can be used to improve the energy efficiency of buildings.

- Automotive: Polymers are used in a wide range of automotive applications, such as engine parts, body panels, and tires. They are lightweight, strong and can withstand high temperatures.

- Textiles: Polymers are used to make synthetic fibers such as nylon and polyester, which are used in clothing, upholstery, and carpets. They are lightweight, strong, and easy to care for.

- Medical: Polymers are used in a wide range of medical applications, such as implants, prosthetics, and drug delivery systems. They are biocompatible, and can be designed to have specific properties such as biodegradability.

- Electronics: Polymers are used in electronic devices such as LCD screens, solar cells, and batteries. They are lightweight, strong, and can be made to have specific electrical properties.

- Adhesives and coatings: Polymer are used in adhesives and coatings to provide a strong bond between different materials. They can be formulated to have specific properties such as UV resistance, flexibility and water resistance.

- Personal care and cosmetic: Polymer are used in personal care products such as hair gels, lotions, and toothpaste. They can be formulated to have specific properties such as thickening, emulsifying and stabilizing.

- Agriculture: Polymer are used in agriculture, for example as mulch films to reduce water evaporation, to control weeds and for soil erosion control.

This is not an exhaustive list, and polymer have many other uses as well. New uses for polymers are being developed all the time, as scientists and engineers continue to find new ways to take advantage of their unique properties.

Working of Polymers

The working of polymers depends on their specific properties and the application they are used in. In general, polymers can be used in several ways, such as:

- As a structural material: Polymer can be used to create a wide range of structures, such as pipes, automotive parts, and buildings. These structures are usually lightweight and strong, and can be molded into complex shapes.

- As a barrier material: Polymer can be used to create barriers that protect products from moisture, oxygen, and other gases. This is done by using a polymer film or coating that creates a barrier around the product.

- As a lubricant: Some polymers have low friction properties and can be used as lubricants in automotive and industrial applications.

- As a packaging material: Polymer can be used to create packaging materials that protect products from damage, such as plastic bags, bottles, and containers.

- As an insulation material: Polymer can be used to create insulation materials that help to reduce heat loss in buildings and electrical equipment.

- As a coating: Polymer can be used as coatings in products such as paints, varnishes, and inks. They provide protection, color, and other specific properties.

- As an adhesive: Polymer can be used as adhesives to bind different materials together. They can be formulated to have specific properties such as waterproofing and UV resistance.

- As a medical device: Polymer can be used in medical applications such as implants, prosthetics and drug delivery systems. They can be designed to have specific properties such as biodegradability and biocompatibility.

- As a fiber: Polymer can be used to create fibers that are used in textiles, such as nylon and polyester. They are lightweight, strong, and easy to care for.

In general, the working of polymer is based on their properties, and scientists and engineers can tailor these properties to meet the specific needs of the application they are used in.