Composite piping systems have revolutionized many industries by offering advanced materials that provide superior performance compared to traditional metallic pipes. These systems, made from a combination of materials such as fibers and resins, are designed to take advantage of the best properties of each component. This blog explores the history, development, and applications of composite piping systems, along with their benefits and future potential.

Historical Background

Early Developments

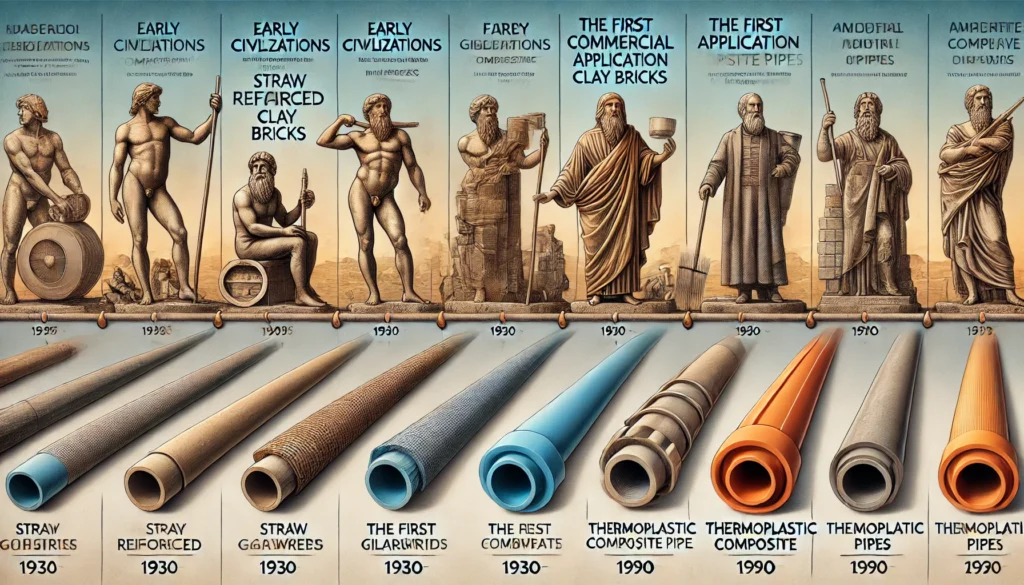

The concept of composite materials dates back to ancient times. Early civilizations used composites in construction, such as straw reinforced clay bricks and the use of animal hair to strengthen mud bricks. However, the modern era of composite materials began in the 20th century with the advent of synthetic resins and high-performance fibers.

In the 1930s, the development of fiberglass marked a significant milestone. Fiberglass, composed of fine glass fibers woven into a fabric and embedded in a resin matrix, provided excellent strength-to-weight ratios and corrosion resistance. This innovation laid the groundwork for the development of composite piping systems.

The Birth of Composite Piping

The first commercial application of composite piping occurred in the 1940s and 1950s. During World War II, the demand for lightweight and durable materials led to the increased use of fiberglass-reinforced plastics (FRP). These early composite pipes were primarily used in marine applications due to their resistance to seawater corrosion.

In the 1960s, advancements in resin technology and manufacturing processes expanded the use of composite pipes to other industries. The oil and gas sector, in particular, began adopting FRP pipes for handling corrosive fluids and gases, reducing maintenance costs and improving system longevity.

Modern Advancements

The 1980s and 1990s witnessed significant advancements in composite materials. The introduction of advanced fibers such as aramid (e.g., Kevlar) and carbon fibers, along with improved resin systems, enhanced the performance of composite piping systems. These materials provided higher strength, better thermal stability, and increased resistance to chemical degradation.

In recent decades, the development of thermoplastic composite pipes (TCP) has further revolutionized the industry. TCPs, made from continuous fibers embedded in a thermoplastic matrix, offer improved flexibility, ease of installation, and recyclability. These properties make them ideal for various applications, including offshore oil and gas production, chemical processing, and potable water distribution.

Technical Aspects of Composite Piping Systems

Materials and Manufacturing

Composite piping systems are typically made from a combination of fibers (such as glass, carbon, or aramid) and resin matrices (such as epoxy, polyester, or vinyl ester). The choice of materials depends on the specific application requirements, including mechanical strength, chemical resistance, temperature tolerance, and cost considerations.

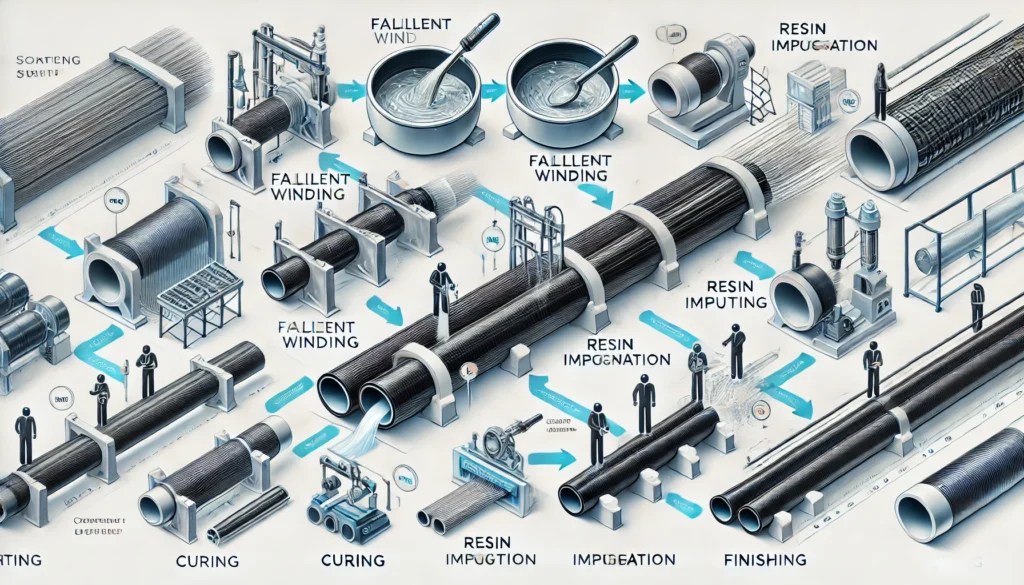

The manufacturing process of composite pipes involves several steps:

- Filament Winding: Continuous fibers are wound around a rotating mandrel in a predetermined pattern. This process ensures uniform fiber distribution and alignment, resulting in high-strength pipes.

- Resin Impregnation: The wound fibers are impregnated with a resin matrix, which binds the fibers together and provides structural integrity. The resin is typically applied using a wet lay-up process or a resin transfer molding (RTM) technique.

- Curing: The resin-impregnated pipe is subjected to heat or UV radiation to cure and harden the resin, forming a solid, durable structure.

- Finishing: The cured pipe is removed from the mandrel, and any necessary finishing operations, such as machining, coating, or joint preparation, are performed.

Properties and Advantages

Composite piping systems offer several advantages over traditional metallic pipes:

- Corrosion Resistance: Composites are inherently resistant to corrosion, making them ideal for handling aggressive chemicals, seawater, and other corrosive fluids.

- Lightweight: Composite pipes are significantly lighter than metal pipes, reducing transportation and installation costs and making them easier to handle in the field.

- High Strength-to-Weight Ratio: The combination of high-strength fibers and lightweight resins results in pipes that offer excellent mechanical performance while remaining relatively light.

- Thermal Insulation: Composite materials have low thermal conductivity, providing inherent insulation properties that can reduce the need for additional insulation in certain applications.

- Design Flexibility: Composite pipes can be manufactured in a wide range of sizes, shapes, and configurations to meet specific design requirements.

- Longevity: The durability and resistance to environmental degradation of composite materials result in longer service life and reduced maintenance costs.

Applications of Composite Piping Systems

Oil and Gas Industry

The oil and gas industry was one of the earliest adopters of composite piping systems. These pipes are used in various applications, including:

- Offshore Platforms: Composite pipes are used for seawater intake, firewater systems, and chemical injection lines on offshore platforms. Their corrosion resistance and lightweight properties make them ideal for harsh marine environments.

- Subsea Pipelines: Thermoplastic composite pipes (TCPs) are increasingly used for subsea pipelines due to their flexibility, ease of installation, and resistance to external pressures and chemical attack.

- Onshore Facilities: Composite pipes are employed in onshore oil and gas facilities for handling corrosive fluids, reducing the risk of leaks and minimizing maintenance requirements.

Chemical Processing

In the chemical processing industry, composite piping systems are used to transport corrosive chemicals and aggressive fluids. Applications include:

- Acid and Alkali Transport: Composite pipes are resistant to a wide range of acids and alkalis, making them suitable for transporting these substances in chemical plants and refineries.

- Process Piping: Composite pipes are used for process piping in chemical plants, where they provide reliable performance and reduce the risk of corrosion-related failures.

Water and Wastewater Treatment

Composite piping systems are increasingly used in water and wastewater treatment facilities for applications such as:

- Potable Water Distribution: Composite pipes are suitable for potable water distribution systems due to their corrosion resistance, smooth internal surfaces (reducing biofilm formation), and long service life.

- Wastewater Treatment: Composite pipes are used in wastewater treatment plants for handling corrosive wastewater and chemicals, ensuring reliable performance and reducing maintenance costs.

Marine and Shipbuilding

The marine industry has long recognized the benefits of composite piping systems. Applications include:

- Ballast Water Systems: Composite pipes are used in ballast water systems on ships, where their corrosion resistance and lightweight properties are advantageous.

- Cooling Water Systems: Composite pipes are employed in ship cooling water systems to transport seawater without the risk of corrosion.

Power Generation

In power generation facilities, composite piping systems are used for various applications, including:

- Cooling Water Systems: Composite pipes are used in cooling water systems for power plants, where their resistance to corrosion and scaling is beneficial.

- Flue Gas Desulfurization (FGD) Systems: Composite pipes are employed in FGD systems to transport corrosive slurries and gases, ensuring reliable performance and reducing maintenance costs.

Challenges and Future Trends

Challenges

Despite the numerous advantages, composite piping systems face some challenges:

- Initial Cost: The initial cost of composite pipes can be higher than traditional metallic pipes. However, the long-term savings in maintenance and longevity often offset this initial investment.

- Jointing and Installation: The jointing and installation of composite pipes require specialized techniques and equipment, which can increase installation complexity and costs.

- Design Standards: The lack of standardized design codes and guidelines for composite piping systems can pose challenges for engineers and designers.

Future Trends

The future of composite piping systems looks promising, with several trends driving their adoption:

- Advanced Materials: Continued advancements in fiber and resin technologies will enhance the performance and durability of composite pipes, making them suitable for even more demanding applications.

- Sustainability: The growing focus on sustainability and environmental impact is driving the development of recyclable and environmentally friendly composite materials.

- Smart Piping Systems: The integration of sensors and monitoring technologies into composite pipes will enable real-time monitoring of pipe conditions, improving maintenance and reducing the risk of failures.

- Expanded Applications: As composite materials and manufacturing techniques continue to improve, the range of applications for composite piping systems will expand, encompassing new industries and challenging environments.

Conclusion

Composite piping systems have come a long way since their early development in the mid-20th century. The combination of high-strength fibers and durable resins has resulted in pipes that offer superior performance, corrosion resistance, and longevity compared to traditional metallic pipes. Today, composite pipes are used in a wide range of industries, from oil and gas to chemical processing, water treatment, marine, and power generation.

The continued advancements in composite materials and manufacturing processes promise even greater performance and sustainability in the future. As industries increasingly recognize the benefits of composite piping systems, their adoption is expected to grow, driving innovation and expanding their applications.

In summary, composite piping systems represent a significant technological advancement, offering a combination of properties that meet the demanding requirements of modern industrial applications. With ongoing research and development, these systems are poised to play an even more critical role in the future, addressing the challenges of corrosion, weight, and environmental impact while delivering reliable and long-lasting performance.