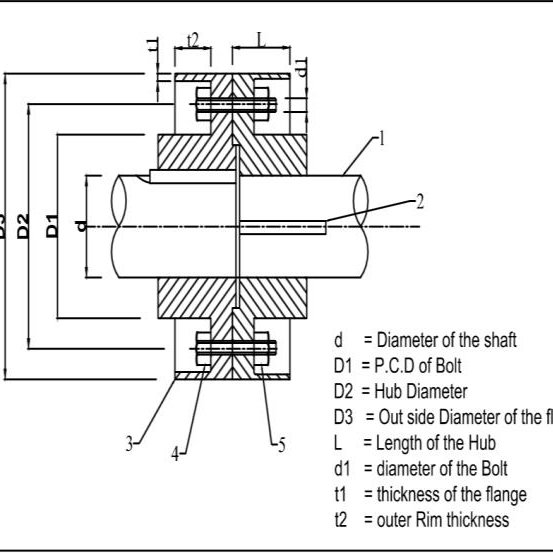

Flange bolt torque calculation is the process of determining the amount of torque that should be applied to the bolts of a flange connection in order to properly seal the joint and prevent leaks. This calculation takes into account several factors, including the size and material of the bolts, the pressure and temperature of the fluid or gas in the pipe, and the type of flange being used.

The first step in flange bolt torque calculation is to determine the required preload or tension on the bolts. This can be done using a formula that takes into account the size and material of the bolts, as well as the pressure and temperature of the fluid or gas in the pipe. Once the required preload is known, the torque required to achieve this preload can be calculated using a torque coefficient, which takes into account the type of flange being used and the condition of the bolts and threads.

To ensure a proper seal and prevent leaks, it is important to use the correct torque when tightening the bolts on a flange connection. This can be done using a torque wrench, which is a tool that measures the amount of torque applied to a bolt as it is tightened. The torque should be applied in a gradual and consistent manner, and the bolts should be tightened in a specific sequence, usually in a cross pattern, to ensure even distribution of load on the flange face.

It’s important to note that the torque calculation is highly dependent on the type of flange, the type of bolting, the size and material of the bolts, the pressure and temperature of the fluid or gas, and the condition of the bolts and threads. Therefore, it’s important to follow the manufacturer’s recommendations, industry standards, and/or consulting a professional engineer.

Working of Flange Bolt Torque Calculation

The torque required to properly tighten a flange bolt is determined by the clamping force required to seal the flange and the friction between the bolt and the flange. The clamping force is determined by the pressure rating of the flange, the size and material of the flange and the gasket, and the operating conditions of the system. The friction is determined by the materials of the bolt and the flange, as well as the surface finish and lubrication of the bolt threads.

To calculate the torque required for a specific flange and bolt combination, the following formula is commonly used:

Torque (lb-ft) = Clamping Force (lb) x 12 / (3.14 x Diameter (in))

Where:

Clamping Force is the force required to seal the flange and is usually specified by the flange manufacturer or industry standards.

Diameter (D) is the diameter of the bolt being used.

It’s important to note that, this is an approximate formula and the actual torque may vary depending on the materials and lubrication, and the actual usage conditions. It’s always advisable to consult the manufacturer’s specifications or industry standards for the recommended torque for a specific flange and bolt combination.

Flange Bolt Torque Calculation Equation

The equation for flange bolt torque calculation typically involves determining the required preload or tension on the bolts, and then using that value to calculate the torque required to achieve that preload.

The formula for determining the required preload or tension on the bolts is:

Preload (lb) = K x D x P

Where: K = a spring constant that takes into account the size and material of the bolts (lb/inch) D = the diameter of the bolts (inches) P = the internal pressure of the fluid or gas in the pipe (psi)

Once the required preload is known, the torque required to achieve that preload can be calculated using a torque coefficient, which takes into account the type of flange being used and the condition of the bolts and threads. The formula for this calculation is typically:

Torque (lb-ft) = K x Preload (lb) x D (inches)

Where: K = torque coefficient (usually provided by the manufacturer or industry standards)

It’s important to note that the equation may vary depending on the type of flange, the type of bolting, the size and material of the bolts, and the condition of the bolts and threads. Therefore, it’s important to follow the manufacturer’s recommendations, industry standards, and/or consulting a professional engineer.

Nut Factor on Flange Bolt Torque Calculation

The nut factor (K factor) is a coefficient that is used to account for the condition of the threads and the effect of lubrication on the flange bolts during torque calculation. The nut factor is used in conjunction with the torque coefficient to provide a more accurate calculation of the torque required to achieve a given preload or tension on the bolts.

The nut factor is a dimensionless value that ranges between 0.2 and 1.0, with a value of 1.0 indicating perfect threads and lubrication, and a value of 0.2 indicating poor threads and no lubrication. The nut factor is determined by the manufacturer or industry standards, depending on the type of flange, the type of bolting, the size and material of the bolts, and the condition of the threads.

The formula for torque calculation with nut factor included is:

Torque (lb-ft) = K x K_nut x Preload (lb) x D (inches)

Where: K = torque coefficient (usually provided by the manufacturer or industry standards) K_nut = nut factor (usually provided by the manufacturer or industry standards)

It’s important to note that the nut factor is only needed when the bolts are not lubricated, in most cases lubrication is applied, thus the nut factor is not needed, and the torque is calculated with only the torque coefficient. Therefore, it’s important to follow the manufacturer’s recommendations, industry standards, and/or consulting a professional engineer.

Pipe Flange Bolt Torque Chart

The torque required for a flange bolt can vary depending on the size and material of the bolt and flange, as well as the application and operating conditions. It’s important to consult the manufacturer’s specifications or industry standards for the recommended torque for a specific flange and bolt combination. Additionally, a torque wrench should be used to ensure the bolts are tightened to the proper torque.

Advantages and Disadvantages Flange Bolt Torque Calculation

Advantages of flange bolt torque calculation:

Ensures proper clamping force: By calculating the precise torque required, the flange bolts can be tightened to the appropriate level, ensuring that the flange is properly sealed and the system is safe to operate.

Improves reliability: By ensuring that the flange is properly sealed, the risk of leaks and other problems is reduced, improving the overall reliability of the system.

Increases safety: By preventing leaks and other problems, the risk of accidents and injuries is reduced, making the system safer to operate.

Saves time and resources: By calculating the precise torque required, the flange bolts can be tightened more efficiently, saving time and resources.

Disadvantages of flange bolt torque calculation:

Complexity: Determining the precise torque required can be a complex process, requiring specialized knowledge and equipment.

Cost: The equipment and expertise required to calculate the precise torque can be expensive.

Variability: The torque required may vary depending on the specific materials and lubrication used, and the actual usage conditions, making it difficult to determine the precise torque required in all cases.

Human error: The process of torque calculation and tightening of bolts need to be performed by trained personnel and there is always a chance of human error.

It’s important to note that, these are general advantages and disadvantages and the actual impact may vary depending on the specific application and usage conditions. It’s always advisable to consult the manufacturer’s specifications or industry standards for the recommended torque for a specific flange and bolt combination.

Application of Flange Bolt Torque Calculation

Flange bolt torque calculation is used in many industrial applications where a flange is used to connect two sections of pipe or equipment. These applications include:

Piping systems: In piping systems, flange bolt torque calculation are used to connect sections of pipe and to provide a seal against leaks. The torque required to properly tighten the flange bolts is critical in ensuring that the system is safe to operate and that leaks are prevented.

Pressure vessels: In pressure vessels, flange bolt torque calculation are used to connect sections of the vessel and to provide a seal against leaks. The torque required to properly tighten the flange bolts is critical in ensuring that the vessel is safe to operate and that leaks are prevented.

Power generation: In power generation, flange bolt torque calculation are used in a variety of applications, including connecting sections of pipe in steam and water systems, and connecting sections of equipment in turbine and generator systems. The torque required to properly tighten the flange bolts is critical in ensuring that the system is safe to operate and that leaks are prevented.

Oil and gas: In oil and gas industry, flange bolt torque calculation are used in a variety of applications, including connecting sections of pipe in production, transportation and refining systems, and connecting sections of equipment in drilling, production and refining systems. The torque required to properly tighten the flange bolts is critical in ensuring that the system is safe to operate and that leaks are prevented.

Chemical processing: In chemical processing, flange bolt torque calculation are used to connect sections of pipe and equipment and to provide a seal against leaks. The torque required to properly tighten the flange bolts is critical in ensuring that the system is safe to operate and that leaks are prevented.

It’s important to note that, these are general applications and the actual usage may vary depending on the specific application and usage conditions. It’s always advisable to consult the manufacturer’s specifications or industry standards for the recommended torque for a specific flange and bolt combination.