H-beam vs I-beam : Features, Similarities, Differences – A Precise and Informative Comparative Study

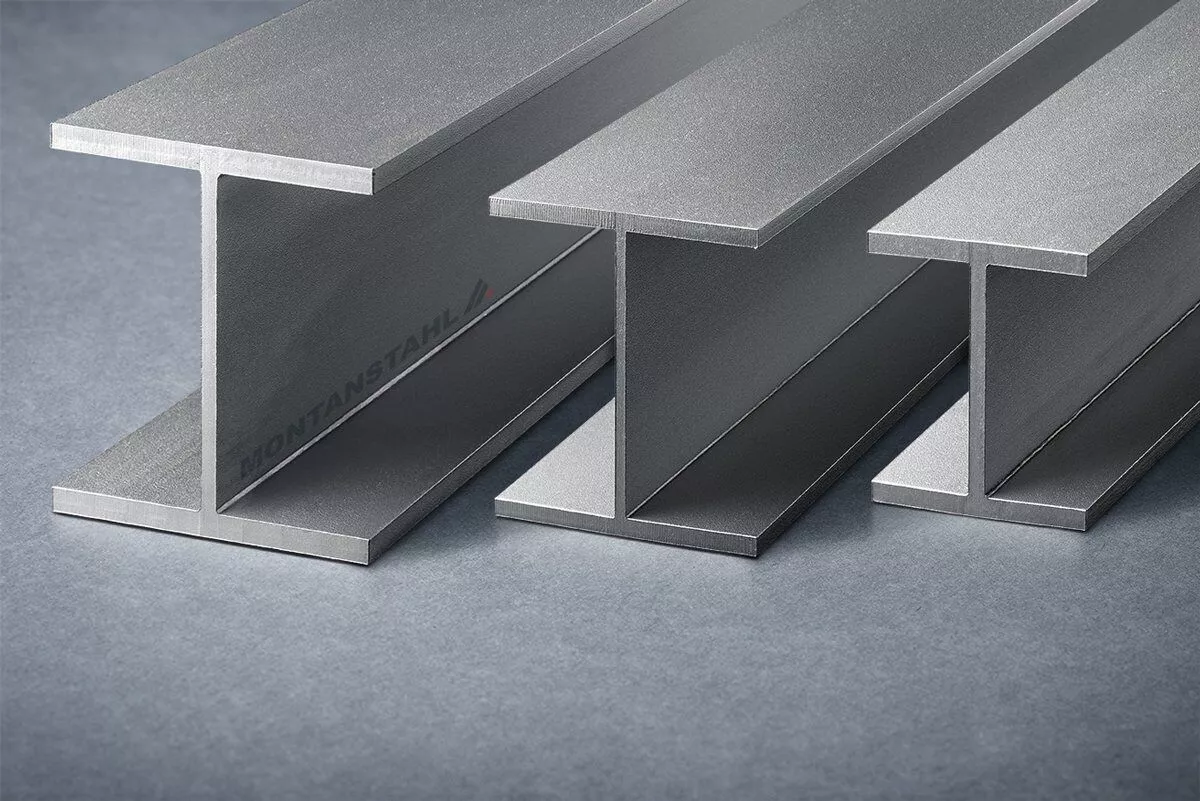

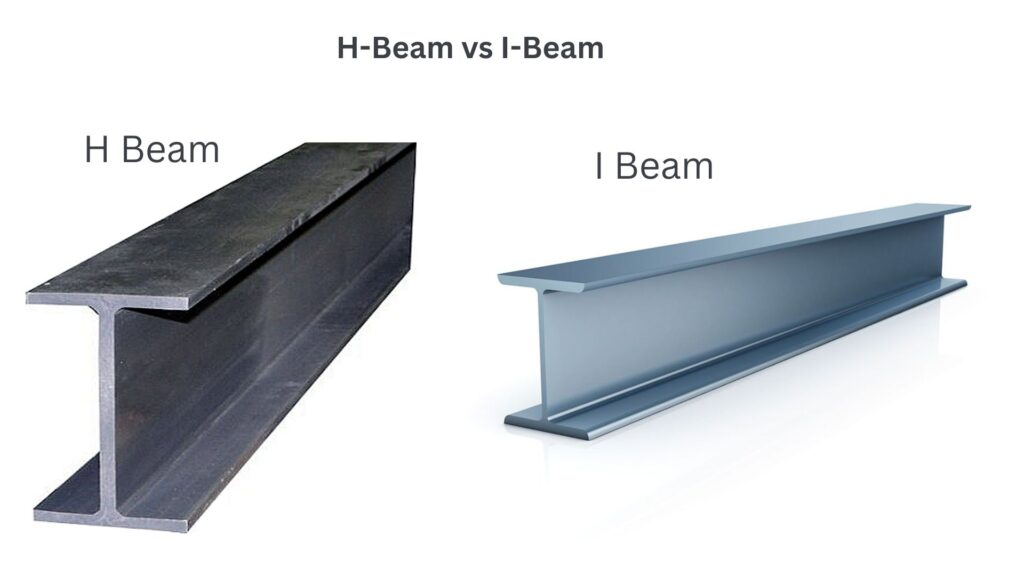

H-beams and I-beams are both types of structural steel commonly used in construction. The main difference between the two lies in their shape, with the H-beam having a wider flange (the horizontal section) compared to the I-beam. The flange of the H-beam has a thickness that is greater in the center and tapers towards the edges. In contrast, the I-beam has a flange that is thinner and a web (the vertical section) that is thicker.

The H-beam is often favored for its ability to withstand large loads and is commonly used in the construction of buildings, bridges, and other large structures. On the other hand, the I-beam is ideal for smaller structures such as beams and columns due to its ability to support light to moderate loads. The choice between the two depends on the specific requirements of the project and the loads that the structure will be subjected to.

Further we’ll explore the topic H-Beam vs I-Beam.

Features and Properties

H-Beam

The H-beam, also known as the wide-flange beam, is a structural steel that has several key features and properties that make it a popular choice for construction:

- Wide Flange: The H-beam’s most distinct feature is its wide flange, which gives it a larger surface area to distribute loads over compared to other types of beams. This makes it ideal for supporting large structures that require a lot of strength and stability.

- High Load-Bearing Capacity: Due to its wide flange, the H-beam is able to bear heavy loads without bending or deforming, making it suitable for use in bridges, high-rise buildings, and other heavy-duty structures.

- Stiffness: The H-beam’s stiffness makes it ideal for use in long-span structures, such as bridges, where it helps to reduce deflection and prevent excessive movement under load.

- Weldability: The H-beam is relatively easy to weld, making it ideal for use in structures that require intricate welding patterns or those that require frequent maintenance.

- Versatility: The H-beam is available in a variety of sizes and shapes, making it suitable for use in a wide range of structures, from small residential buildings to large industrial complexes.

- Durability: The H-beam is made from high-quality structural steel that is resistant to corrosion, making it a durable choice for use in structures that will be exposed to harsh weather conditions.

- Cost-Effectiveness: The H-beam is relatively cost-effective compared to other types of structural steel, making it a budget-friendly option for those who are looking to save money on construction costs.

I-Beam

The I-beam, also known as the H-beam, is a structural steel that has several key features and properties that make it a popular choice for construction:

- Narrow Flange: The I-beam has a narrow flange, which makes it ideal for use in smaller structures where a smaller surface area is required to distribute loads.

- High Strength-to-Weight Ratio: The I-beam has a high strength-to-weight ratio, meaning it is able to support a significant amount of weight while being relatively lightweight. This makes it ideal for use in structures where weight is a concern, such as bridges, towers, and high-rise buildings.

- Stiffness: The I-beam’s stiffness makes it ideal for use in short-span structures, such as beams and columns, where it helps to prevent bending and deformation under load.

- Weldability: The I-beam is relatively easy to weld, making it ideal for use in structures that require intricate welding patterns or those that require frequent maintenance.

- Versatility: The I-beam is available in a variety of sizes and shapes, making it suitable for use in a wide range of structures, from small residential buildings to large industrial complexes.

- Durability: The I-beam is made from high-quality structural steel that is resistant to corrosion, making it a durable choice for use in structures that will be exposed to harsh weather conditions.

- Cost-Effectiveness: The I-beam is relatively cost-effective compared to other types of structural steel, making it a budget-friendly option for those who are looking to save money on construction costs.

This deep understanding and information will help us explore our key topic H-Beam vs I-Beam.

Similarities

- Both H-beams and I-beams are structural steel beams used in construction.

- Both types have a similar shape with a web (the central portion of the beam) and flange (the horizontal projecting parts at top and bottom of the web) to provide strength and stability.

- Both can be used as support beams for bridges, buildings, and other structures, and to transfer loads from one support to another.

- Both are made from rolled steel and are commonly used for large construction projects due to their strength, durability and ability to support heavy loads.

- Both can be made from a variety of materials including steel, stainless steel, and aluminum, and can be finished with paint or a protective coating to increase resistance to weathering and corrosion.

- Both H-beams and I-beams can be customized to meet specific design requirements, including size, length, and load-bearing capabilities.

Finally, we’ll explore our key topic H-Beam vs I-Beam better.

H-Beam vs I-Beam : A Comparative Study

H-Beams and I-Beams are two of the most widely used types of structural steel beams in construction. Both are made from high-strength rolled steel and are commonly used for large construction projects due to their strength, durability, and ability to support heavy loads. However, there are some key differences between H-beams and I-beams that should be considered when choosing the best type of beam for a particular application. H-Beam vs I-Beam:

- Shape: H-beams have a wider web and shorter flanges compared to I-beams, while I-beams have a narrower web and longer flanges. This means that H-beams are generally stronger and better suited for applications where heavy loads need to be transferred, while I-beams are more flexible and are better suited for applications where a high degree of bending is required.

- Load-bearing capacity: H-beams have a higher load-bearing capacity and are better suited for applications where heavy loads need to be transferred, such as bridges, buildings, and other structures. I-beams are better suited for applications where loads are mainly perpendicular to the beam axis, such as floor beams and rafters.

- Availability of sizes: H-beams are available in a wider range of sizes compared to I-beams, making them a better choice for large construction projects where custom sizes may be required. I-beams are typically limited to specific sizes, which can make them less versatile.

- Cost: H-beams are typically more expensive compared to I-beams due to the increased size and weight of the material. I-beams are typically less expensive due to their smaller size and weight, making them a more cost-effective option for smaller projects or applications where budget is a concern.

- Flexibility: H-beams are less flexible compared to I-beams and are better suited for applications where stability is required. I-beams are more flexible and are better suited for applications where a high degree of bending is required.

In conclusion, the choice between H-beams vs I-beams will depend on the specific requirements of the application, including load-bearing capacity, flexibility, and cost. An engineer or contractor should carefully consider these factors when selecting the best type of beam for a particular project. This deep understanding and information will help us explore our key topic H-Beam vs I-Beam : A comparative table.

| Feature | H-Beam | I-Beam |

| Shape | The web of an H-beam is wider and flanges are shorter compared to an I-beam. | The web of an I-beam is narrower and flanges are longer. |

| Load-bearing capacity | H-beams have a higher load-bearing capacity and are better suited for applications where heavy loads need to be transferred. | I-beams are better suited for applications where loads are mainly perpendicular to the beam axis. |

| Availability of sizes | H-beams are available in a wider range of sizes compared to I-beams. | I-beams are typically limited to specific sizes. |

| Cost | H-beams are typically more expensive compared to I-beams due to the increased size and weight of the material. | I-beams are typically less expensive compared to H-beams due to their smaller size and weight. |

| Flexibilty | H-beams are less flexible compared to I-beams and are better suited for applications where stability is required. | I-beams are more flexible and are better suited for applications where a high degree of bending is required. |

H-Beam Size Chart

Here is a chart showing the dimensions for common sizes of H-beams:

| H-Beam Size (Inches) | Flange Width | Web Thickness | Flange Thickness |

| 6 x 6 | 5.5 | 0.17 | 0.17 |

| 8 x 8 | 7.5 | 0.2 | 0.2 |

| 10 x 10 | 9.5 | 0.24 | 0.24 |

| 12 x 12 | 11.5 | 0.28 | 0.28 |

| 14 x 14 | 13.5 | 0.32 | 0.32 |

| 16 x 16 | 15.5 | 0.36 | 0.36 |

| 18 x 18 | 17.5 | 0.4 | 0.4 |

| 20 x 20 | 19.5 | 0.44 | 0.44 |

| 22 x 22 | 21.5 | 0.48 | 0.48 |

I-Beam Size Chart

Here is a chart showing the dimensions for common sizes of I-beams:

| I-Beam Size (Inches) | Depth (inches) | Flange Width (inches) | Web Thickness (inches) |

| 4 x 4 | 4 | 4 | 0.2 |

| 5 x 5 | 5 | 5 | 0.2 |

| 6 x 6 | 6 | 6 | 0.2 |

| 8 x 8 | 8 | 8 | 0.2 |

| 10 x 10 | 10 | 10 | 0.3 |

| 12 x 12 | 12 | 12 | 0.3 |

| 14 x 14 | 14 | 14 | 0.3 |

| 16 x 16 | 16 | 16 | 0.4 |

| 18 x 18 | 18 | 18 | 0.4 |

| 20 x 20 | 20 | 20 | 0.4 |

| 22 x 22 | 22 | 22 | 0.4 |

Conclusion

In the H-Beam vs I-Beam comparison, the primary difference between H-beams and I-beams is their shape and size. H-beams have a wider flange and a smaller web, while I-beams have a deeper depth and a wider web.

H-beams are commonly used for large construction projects, such as building support structures in commercial and industrial facilities. Their wide flange provides excellent support, making them suitable for horizontal loads, while their narrow web allows for more efficient use of material, reducing cost.

I-beams are commonly used in residential and commercial construction projects, as well as for bridge construction. They have a deep depth, which provides additional strength and support, making them ideal for vertical loads. Additionally, their wider web provides more stability and reduces the risk of buckling.

In terms of cost, H-beams tend to be more expensive than I-beams, due to the additional material required to make the wider flange. However, the cost difference can be offset by the reduced amount of material required for the web.

In conclusion to the H-Beam vs I-Beam argument, both H-beams and I-beams have their own unique benefits and uses. The choice between the two will depend on the specific requirements of the project, including the load conditions, the size and shape of the structure, and the desired level of strength and stability. It’s important to consult with a structural engineer or contractor to determine the best option for your project.