Piping systems are the unsung heroes of modern infrastructure, enabling the transportation of fluids and gases efficiently and safely across various applications. From ancient aqueducts to contemporary industrial networks, piping systems have evolved remarkably, reflecting advancements in engineering, materials science, and technology. This blog explores the rich history, types, advantages, disadvantages, and diverse applications of piping systems, underscoring their indispensable role in our daily lives.

A Historical Perspective

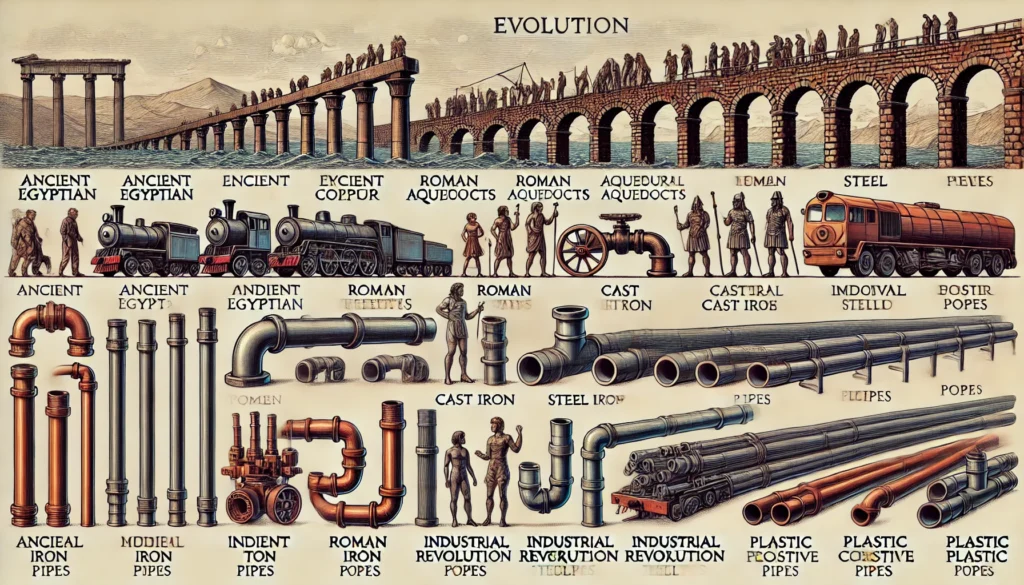

The history of piping systems dates back to ancient civilizations, where early innovations laid the foundation for contemporary plumbing and industrial applications. Around 4000 BCE, the ancient Egyptians pioneered the use of copper pipes for irrigation and water transport. They utilized hollowed-out palm logs and copper piping to transport water from the Nile River to fields and gardens, demonstrating early engineering prowess.

The Greeks and Romans further advanced piping systems, with the Romans developing extensive aqueduct systems by 312 BCE. These aqueducts, made of stone, brick, and lead pipes, were engineering marvels, transporting water over long distances to cities, public baths, fountains, and private homes. The sophistication of Roman plumbing was unparalleled, with systems that included lead pipes and even early forms of valves and taps.

During the Middle Ages, the progress in piping systems slowed due to the decline of Roman engineering practices. However, the Renaissance era sparked renewed interest and innovation in plumbing. By the 17th century, the introduction of cast iron pipes in Europe marked a significant advancement. These pipes were initially used for drainage and sewage systems, demonstrating improved durability over previous materials.

The Industrial Revolution in the 19th century was a pivotal period for piping systems. The development of steam engines and industrial machinery necessitated the creation of robust and reliable piping networks. Cast iron, wrought iron, and steel became the materials of choice for industrial piping systems, capable of withstanding high pressures and temperatures. The invention of welding techniques in the late 19th century further revolutionized piping construction, allowing for seamless and leak-proof connections.

Types of Piping Systems

Piping systems are categorized based on their materials, applications, and design. Understanding these distinctions is crucial for selecting the appropriate system for specific needs.

1. Metal Piping Systems

- Copper: Known for its corrosion resistance and thermal conductivity, copper piping systems are widely used in plumbing and HVAC applications. They are easy to install, durable, and recyclable, making them an eco-friendly choice.

- Steel: Steel pipes, including carbon steel and stainless steel variants, are prominent in industrial applications. They offer high strength, durability, and resistance to extreme temperatures and pressures. Stainless steel is particularly favored for its corrosion resistance.

- Cast Iron: Traditionally used for drainage and sewer systems, cast iron pipes are valued for their durability and sound-dampening properties. However, their susceptibility to corrosion and brittleness are notable drawbacks.

2. Plastic Piping Systems

- PVC (Polyvinyl Chloride): PVC pipes are popular in residential and commercial plumbing due to their affordability, corrosion resistance, and ease of installation. They are commonly used for cold water supply and drainage systems.

- CPVC (Chlorinated Polyvinyl Chloride): Similar to PVC but with enhanced temperature tolerance, CPVC piping systems are suitable for both hot and cold water supply. They are resistant to scaling and chlorine degradation.

- PEX (Cross-Linked Polyethylene): PEX pipes are flexible, making them ideal for retrofit projects and areas with complex layouts. They are used in plumbing, radiant heating, and cooling systems.

3. Composite Piping Systems

- Multilayer Composite: Combining the advantages of metal and plastic, multilayer composite pipes consist of layers of aluminum and plastic. They offer flexibility, durability, and resistance to corrosion and scaling, making them suitable for various applications, including plumbing and heating systems.

Advantages and Disadvantages of Piping Systems

Each type of piping system comes with its own set of pros and cons, influencing their suitability for different applications.

Advantages

- Durability: Modern piping systems, especially those made from metals like steel and copper, offer exceptional durability and longevity, reducing the need for frequent replacements.

- Corrosion Resistance: Materials like stainless steel, copper, and plastic are resistant to corrosion, ensuring the longevity and reliability of the piping system.

- Ease of Installation: Piping systems, particularly plastic variants, are lightweight and easy to install, reducing labor costs and installation time.

- Versatility: With various materials and designs available, piping systems can be tailored to meet the specific requirements of different applications, from residential plumbing to industrial processes.

- Safety: Modern piping systems are designed to withstand high pressures and temperatures, ensuring safe and efficient transport of fluids and gases.

Disadvantages

- Cost: High-quality materials like stainless steel and copper can be expensive, impacting the overall cost of the piping system.

- Susceptibility to Damage: Plastic piping systems, while easy to install, can be prone to damage from external factors like UV radiation and physical impact.

- Maintenance: Some piping systems, particularly those used in industrial applications, require regular maintenance to prevent issues like scaling, corrosion, and leaks.

- Environmental Concerns: The production and disposal of certain piping materials, such as PVC, raise environmental concerns due to their potential impact on the ecosystem.

Usability in Different Places

Piping systems are ubiquitous, playing a crucial role in various settings, from residential homes to industrial plants. Here’s an overview of their applications across different environments.

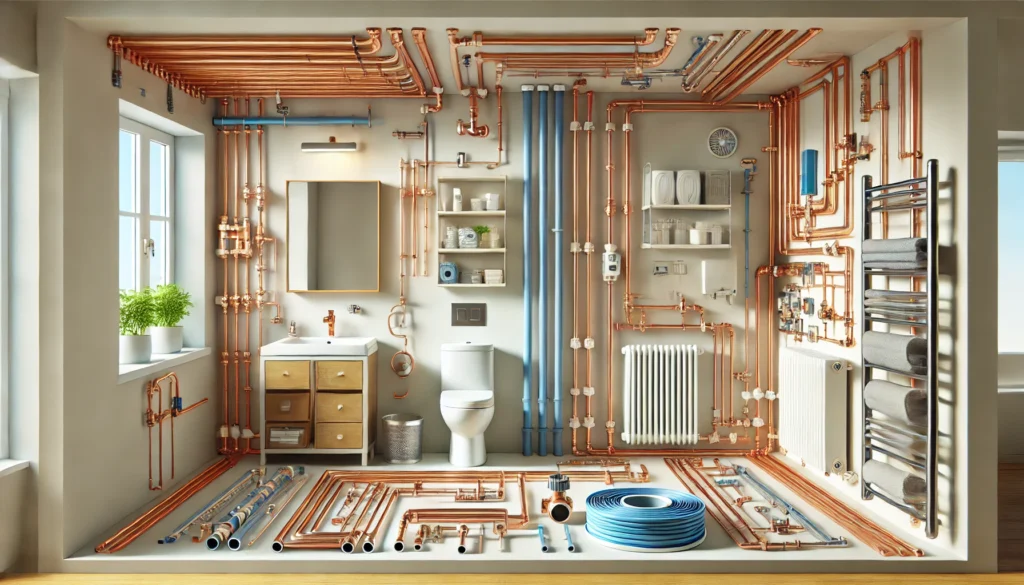

1. Residential

- Plumbing: Piping systems are the backbone of residential plumbing, providing a reliable supply of clean water and efficient drainage. Copper, PVC, and PEX pipes are commonly used in household plumbing.

- Heating and Cooling: PEX and copper pipes are widely used in radiant heating systems and HVAC applications, ensuring efficient thermal regulation.

2. Commercial

- Fire Suppression Systems: Steel and CPVC pipes are integral to fire suppression systems in commercial buildings, offering durability and resistance to high temperatures.

- Waste Management: Cast iron and PVC pipes are used for waste management systems, ensuring efficient sewage and drainage operations in commercial establishments.

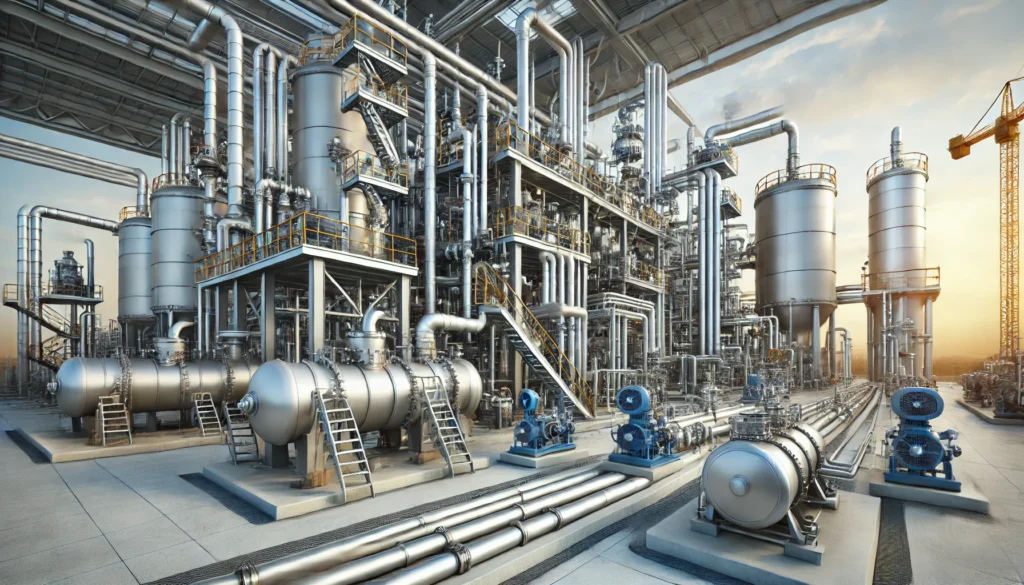

3. Industrial

- Chemical Processing: Stainless steel and composite pipes are essential in chemical processing plants, handling corrosive substances and extreme conditions.

- Oil and Gas: The oil and gas industry relies on robust steel piping systems for the transport of crude oil, natural gas, and refined products. These systems are designed to withstand high pressures and harsh environments.

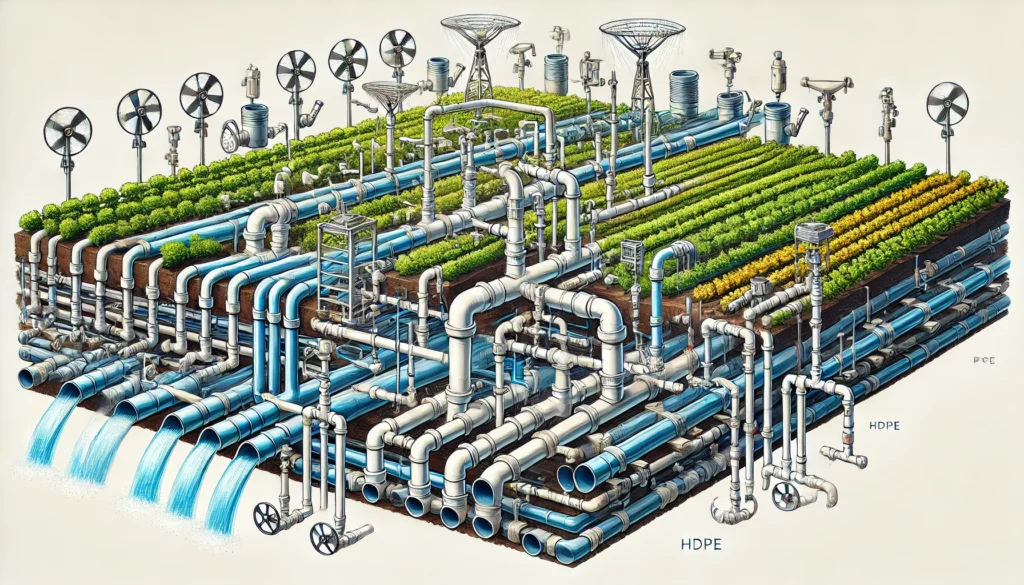

4. Agriculture

- Irrigation: PVC and HDPE (High-Density Polyethylene) pipes are commonly used in agricultural irrigation systems, providing efficient water distribution for crops.

- Water Supply: Reliable piping systems ensure a consistent water supply for livestock and agricultural operations, enhancing productivity and sustainability.

Innovations and Future Trends

The evolution of piping systems continues, driven by technological advancements and the need for sustainable solutions. Emerging trends include:

- Smart Piping Systems: Integration of sensors and IoT (Internet of Things) technology allows for real-time monitoring of piping systems, enabling predictive maintenance and reducing the risk of leaks and failures.

- Eco-Friendly Materials: The development of biodegradable and recyclable piping materials aims to reduce the environmental impact of traditional systems, promoting sustainability.

- Advanced Coatings**: Innovations in coating technologies enhance the corrosion resistance and durability of metal pipes, extending their lifespan and reducing maintenance costs.

- Prefabrication and Modular Construction: Prefabricated piping systems and modular construction techniques streamline installation processes, reducing labor costs and construction time.

Conclusion

Piping systems are integral to the functioning of modern society, facilitating the safe and efficient transport of fluids and gases across diverse applications. From ancient aqueducts to contemporary industrial networks, the evolution of piping systems reflects human ingenuity and technological progress. Understanding the various types, advantages, disadvantages, and applications of piping systems is essential for selecting the right solution for specific needs. As innovation continues to drive the industry forward, the future of piping systems promises enhanced efficiency, sustainability, and reliability, reinforcing their role as the lifeline of infrastructure worldwide.