Stud Bolt : Types, Selection, Materials, and Standards of Stud-Bolt – A Detailed Account its Importance

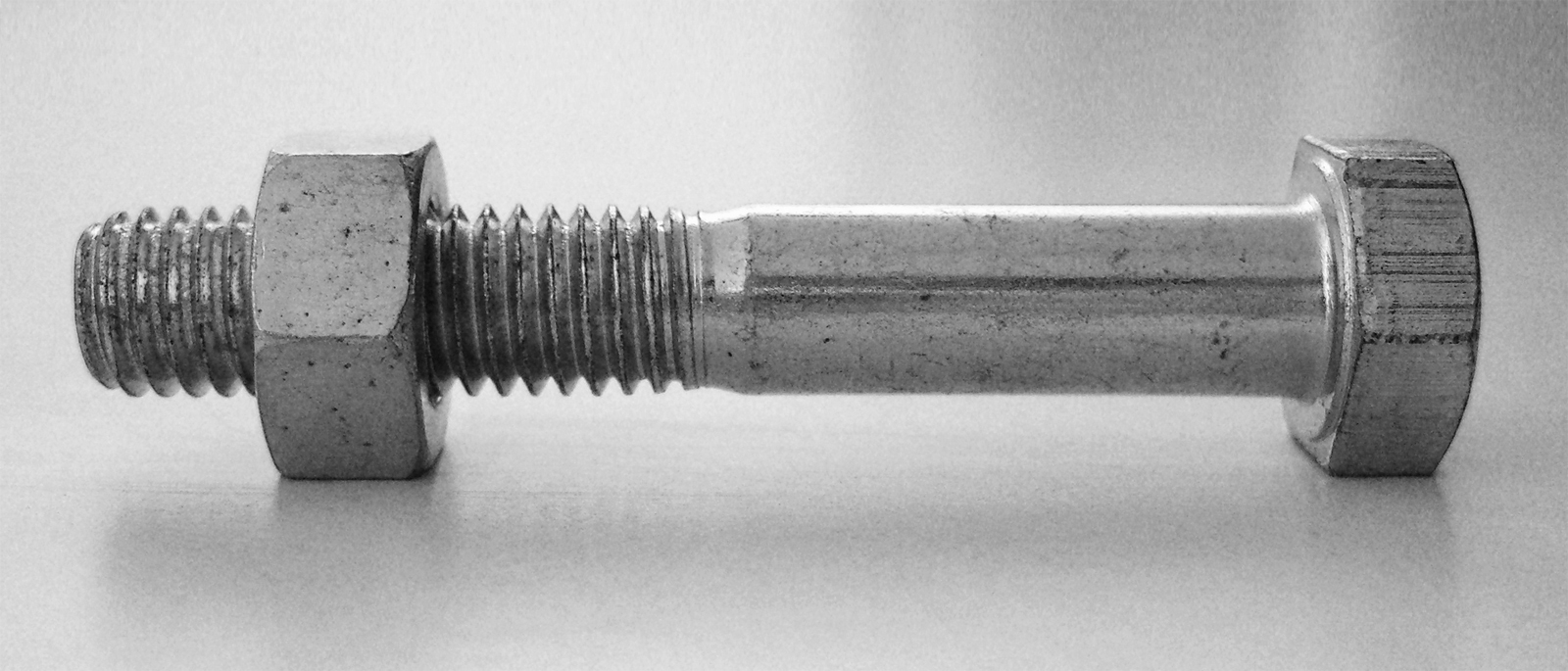

A stud bolt is a specialized fastener utilized in a variety of high-pressure applications, including pipelines, pressure vessels, and related equipment. It is composed of a threaded rod and two heavy hex nuts, as well as a flat or square washer that provides additional stability and support. The rod features threading on both ends, allowing for the secure attachment of the nuts and washer, which work together to provide the necessary clamping force required to maintain a strong and leak-free connection between components.

When used in high-pressure applications, the strength and durability is critical to the success of the overall system. To this end, stud bolts are typically constructed from high-strength materials, such as alloy steel, stainless steel, or inconel, which are able to withstand high temperatures and corrosive environments. The specific size, length, and threading is determined by industry standards, including ASME B16.5, ASME B16.47, and API 6A, to ensure that the bolt is able to meet the exact requirements of the intended application.

Types of Stud Bolts

There are several types of stud bolts that are used for different purposes and applications. Some of the most common types include:

- Double End – This type has threads on both ends, allowing for attachment to both flanges in a pipeline or pressure vessel assembly.

- Single End – Single end stud bolts have threads on one end only and are used when only one flange needs to be attached.

- Full-Thread – These have threads that run the entire length of the rod, providing maximum grip and holding strength.

- Tap End – Tap ends have threads that only extend partway down the rod and are used when a precise grip length is required.

- U-Bolt – These are shaped like a “U” and are commonly used to secure pipes and other cylindrical components.

- Anchor – Anchor stud bolts are designed to provide a secure anchoring point in concrete or other building materials.

- Lifting – These are designed to provide a lifting point for heavy loads and are commonly used in the construction of cranes and other heavy equipment.

Each type is designed to meet specific requirements and is selected based on the specific needs of the application. Factors that are considered when choosing a stud bolt include the type of joint, the size and material of the components being joined, the operating temperature and pressure, and the environmental conditions present in the application.

Selection of Stud Bolts

The selection of stud bolts is an important step in ensuring the proper function and performance of a pipeline, pressure vessel, or other high-pressure equipment. The following factors should be considered when selecting stud bolts:

- Material: The material must be able to withstand the operating temperature, pressure, and corrosive environment of the application. Common materials include alloy steel, stainless steel, and inconel.

- Size: The size must match the size of the flanges or fittings being joined. Industry standards such as ASME B16.5 and ASME B16.47 specify the dimensions for different stud bolts sizes.

- Strength: The strength must be adequate for the pressure and load requirements of the application. Stud bolts are rated based on their tensile strength, yield strength, and hardness.

- Length: The length must match the thickness of the flanges or fittings being joined. Too short or too long a stud bolt can result in a weak or ineffective joint.

- Thread Type: The thread type must match the thread type of the flanges or fittings being joined. Common thread types include UNF, NPT, BSP, and BSPT.

- Application Requirements: Other requirements, such as the need for double-ended or tap-end stud bolts, must be considered based on the specific needs of the application.

It is important to consult with a manufacturer or supplier of stud bolts to ensure that the proper stud bolt is selected for the intended application. In addition, industry standards and codes, such as ASME B16.5, ASME B16.47, and API 6A, should be consulted to ensure that it meets the necessary safety and performance requirements.

Material

The components necessary for a stud bolt assembly consist of several materials, each with their own unique function. These materials include:

- Stud Bolt: The primary component of the assembly, the stud bolt is a threaded rod that is equipped with two heavy hex nuts and a flat or square washer. The rod’s double-ended threading enables the secure attachment of the nuts and washer, which work together to provide a strong, leak-free connection.

- Heavy Hex Nuts: The heavy hex nuts are used to generate clamping force and ensure that the connection remains tight.

- Washer: The washer is utilized to evenly distribute the clamping force and provide a stable surface for the nuts to grip onto.

- Gasket: A gasket is placed between the flanges or fittings being joined to form a seal. It is important to choose a gasket material that is suitable for the fluid or gas being transported and can withstand the application’s operating temperature and pressure.

- Threaded Fasteners: Additional threaded fasteners, such as nuts and bolts, may be necessary to hold its assembly in place on the flanges or fittings.

It is crucial to choose high-quality materials that meet industry standards and are suited to the operating conditions of the application in order to guarantee proper performance and functionality of its assembly.

Standards

The design, material, and testing requirements for stud bolts are regulated by various industry standards. These standards provide specifications for the dimensions and tolerances of the stud bolts, as well as the mechanical properties of the materials used. Some of the most widely recognized standards include:

- ASME B16.5: This standard outlines the specifications for pipe flanges and flanged fittings.

- ASME B16.47: This standard outlines the specifications for large diameter steel flanges.

- API 6A: This standard sets the requirements for wellhead and Christmas tree equipment used in the petroleum and natural gas industries.

- DIN EN ISO 898-1: This standard outlines the mechanical properties of fasteners made of carbon steel and alloy steel.

- ASTM A193: This standard sets the requirements for alloy steel and stainless steel bolts, studs, and other threaded fasteners used in high-temperature or high-pressure applications.

- ASTM A320: This standard sets the requirements for alloy steel and stainless steel bolts, studs, and other threaded fasteners used in low-temperature applications.

In order to ensure proper performance and functionality of the stud bolt assembly, it is crucial to choose stud bolts that comply with the relevant industry standards for the specific application.

Market Value and Economics

The market value and economics of stud bolts depend on various factors, such as the demand for their applications, the availability of materials and manufacturing processes, and the competition in the market. Some of the factors that influence the market value and economics of stud bolts are:

- Demand: The demand for stud bolts is driven by the need for secure and reliable connections in the assembly of pipelines, pressure vessels, and other high-pressure equipment. The growth in the oil and gas, power generation, and construction industries is expected to drive the demand for stud bolts.

- Material and Manufacturing Costs: The cost of raw materials, such as steel and other alloys, and the cost of manufacturing processes, such as forging, casting, and machining, influence the market value and economics of stud bolts.

- Competition: The competition among manufacturers of stud bolts influences the market value and economics, as companies compete to offer the best quality products at competitive prices.

- Innovation: The development of new materials and manufacturing processes can influence the market value and economics of stud bolts by providing better and more cost-effective solutions to meet the demands of the market.

Overall, the market value and economics of stud bolts are influenced by a combination of demand, production costs, competition, and innovation. The exact impact of these factors on the market value and economics of stud bolts can vary depending on regional and global economic conditions.

Companies manufacturing Stud Bolts

There are many companies around the world that manufacture stud bolts. Some of the leading companies in the industry include:

- Baoji Fitow Metal Co., Ltd.

- Hilti Corporation

- Nucor Fastener

- J.I. Morris Company, Inc.

- Bowers Manufacturing Company

- Porteous Fastener Company, Inc.

- U-Bolt-It, Inc.

- BOLTFAST (Pty) Ltd.

- R.E. McDonald Co.

- Thunder Threads, LLC

These companies offer a wide range of stud bolts and other fastening solutions, catering to various industries such as oil and gas, power generation, construction, and others. They have a strong reputation for providing high-quality products and excellent customer service, and are committed to meeting the demands of their customers.

Conclusion

A stud bolt is a type of fastener used to join flanges, fittings, and other components in high-pressure equipment such as pipelines and pressure vessels. It consists of a threaded rod with two heavy hex nuts and a flat or square washer. They are usually made from high-strength materials like alloy steel, stainless steel, or inconel to withstand high temperatures and corrosive environments.

Their selection is based on factors such as the size, length, and threading of the bolt, the operating conditions of the application, and the relevant industry standards, such as ASME B16.5, ASME B16.47, and API 6A.

Their market value and economics are influenced by factors such as demand, material and manufacturing costs, competition, and innovation. The exact impact of these factors can vary depending on regional and global economic conditions. It is important to select high-quality materials and stud bolts that meet industry standards to ensure proper performance and functionality.